Ukubekwa kwezandla yinkqubo yokubumba ye-FRP elula, eyongayo nesebenzayo engadingi zixhobo ezininzi kunye notyalo-mali oluyinkunzi kwaye inokuzuza imbuyekezo kwinkunzi ngexesha elifutshane.

1.Ukutshiza kunye nokupeyinta kwengubo yegel

Ukuze kuphuculwe kwaye kuhonjiswe umgangatho wemveliso ye-FRP, ukwandisa ixabiso lemveliso, kunye nokuqinisekisa ukuba umaleko wangaphakathi we-FRP awukhukulwanga kwaye wandise ubomi benkonzo yemveliso, indawo yokusebenza yemveliso yenziwa ngokubanzi. kwimaleko ene-pigment paste (umbala wokuncamathisela), umxholo ophezulu we-resin we-adhesive layer, inokuba yi-resin ecocekileyo, kodwa iphinde iphuculwe ngokuvakala komphezulu.Lo maleko ubizwa ngokuba ngumaleko wengubo yejeli (ekwabizwa ngokuba ngumaleko womphezulu okanye umaleko wokuhombisa).Umgangatho wengubo yengubo ye-gel ichaphazela ngokuthe ngqo umgangatho wangaphandle wemveliso kunye nokuxhathisa imozulu, ukuxhathisa kwamanzi kunye nokuchasana nokukhukuliseka kweekhemikhali kwimidiya, njl. Ngoko ke, ezi ngongoma zilandelayo kufuneka ziqatshelwe xa kutshizwa okanye ukupeyinta ijeli yengubo yengubo.

2.Ukumiselwa kwendlela yenkqubo

Indlela yenkqubo inxulumene nezinto ezahlukeneyo ezifana nomgangatho wemveliso, ixabiso lemveliso kunye nomjikelo wemveliso (ubuchule bokuvelisa).Ngoko ke, ngaphambi kokulungelelanisa imveliso, kuyimfuneko ukuba nokuqonda okubanzi kweemeko zobugcisa (indalo, iqondo lokushisa, eliphakathi, umthwalo ……, njl.), isakhiwo semveliso, ubuninzi bemveliso kunye neemeko zokwakha xa imveliso isetyenziswa, kwaye emva kokuhlalutya. kunye nophando, ukwenzela ukugqiba inkqubo yokubumba inkqubo, ukuthetha ngokubanzi, le miba ilandelayo kufuneka ithathelwe ingqalelo.

3.Umxholo ophambili woyilo lwenkqubo

(1) Ngokweemfuno zobugcisa zemveliso ukukhetha izinto ezifanelekileyo (izinto zokuqinisa, izinto zokwakha kunye nezinye izinto ezincedisayo, njl.).Ekukhethweni kwezinto eziluhlaza, le miba ilandelayo iqwalaselwa ikakhulu.

① Nokuba imveliso inxibelelene ne-asidi kunye ne-alkaline media, uhlobo lwemidiya, ugxininiso, ubushushu bokusebenzisa, ixesha lokunxibelelana, njl.

②Ukuba kukho iimfuno zokusebenza ezifana nokuhanjiswa kokukhanya, ukubuyiswa komlilo, njl.

③Ngokweempawu zomatshini, nokuba ngumthwalo oguqukayo okanye omileyo.

④Ngaphandle okanye ngaphandle kothintelo lokuvuza kunye nezinye iimfuno ezikhethekileyo.

(2) Qinisekisa ubume bokubumba kunye nezinto eziphathekayo.

(3) Ukhetho lwe-arhente yokukhulula.

(4) Qinisekisa i-resin yokunyanga efanelekileyo kunye nenkqubo yokunyanga.

5

(6) Ukulungiswa kweenkqubo zokubumba.

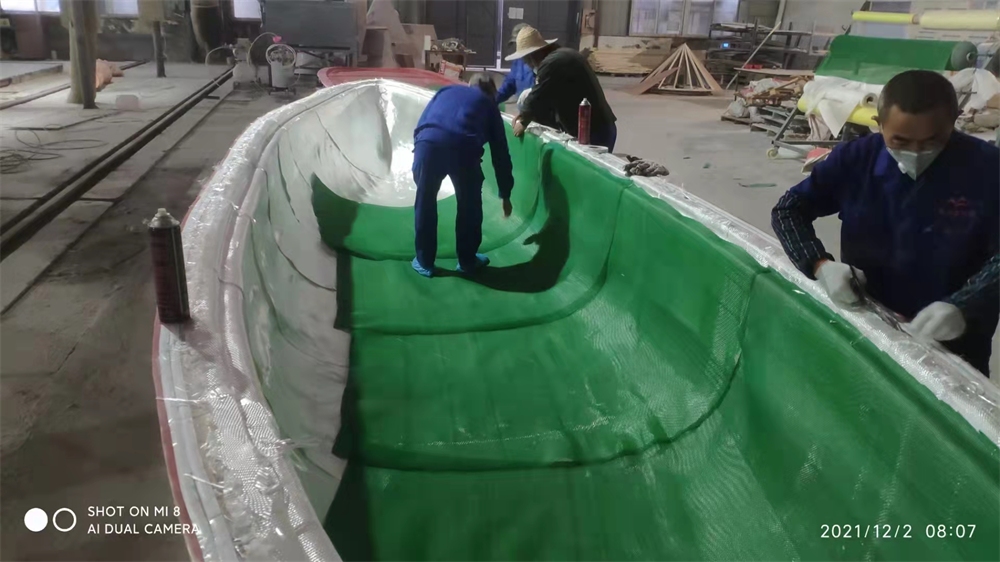

4. Ifayibha yeglasi eyomelezwe inkqubo yokuncamathelisa umaleko weplastiki

Ukubekwa kwezandla yinkqubo ebalulekileyo yenkqubo yokubumba intlama yezandla, kufuneka ibe nokusebenza kakuhle ukufezekisa ngokukhawuleza, okuchanekileyo, umxholo we-resin efanayo, akukho amaqamza acacileyo, akukho kufakwa kakubi, akukho monakalo kwifayibha kunye nemveliso yomhlaba flat, ukuqinisekisa umgangatho. yeemveliso.Ngoko ke, nangona umsebenzi we-gluing ulula, akulula kakhulu ukwenza iimveliso kakuhle, kwaye kufuneka zithathwe ngokungathí sina.

(1) Ukulawula ukutyeba

Ifiber yeglasiImveliso yeplastiki eyomeleziweyo yokulawula ubukhulu, kuyilo lwenkqubo yokuncamathisela kunye nenkqubo yokuvelisa iya kudibana neengxaki zobugcisa, xa sisazi ubunzima obufunekayo bemveliso, kuyimfuneko ukubala ukugqiba i-resin, isiqulatho sokugcwalisa kunye nezinto zokuqinisa ezisetyenziswa kwiinkcukacha. , inani leeleya.Emva koko ubale ubukhulu bayo obusondeleyo ngokwefomula ilandelayo.

(2) Ukubalwa kwedosi ye-resin

I-resin dosage ye-FRP yiparameter yenkqubo ebalulekileyo, enokubalwa ngeendlela ezimbini ezilandelayo.

Ibalwe ngokomgaqo wokuzaliswa kwesithuba, ifomyula yokubala inani le-resin, yazi kuphela ubunzima beyunithi yendawo yelaphu leglasi kunye nobukhulu obulinganayo (umaleko weiglasiifayibhailaphu elilingana nobukhulu bemveliso), unokubala inani le-resin equlethwe kwi-FRP

B ibalwa ngokuqala ngokubala ubunzima bemveliso kunye nokumisela umxholo wepesenti yobunzima beglasi.

(3)Iglasiifayibhainkqubo yokuncamathelisa ilaphu

Iimveliso ezinomaleko we-gelcoat, i-gelcoat ayinakuxutywa kunye nokungcola, i-paste phambi kokuba inkqubo kufuneka ithintele ukungcola phakathi kwe-gelcoat layer kunye ne-backing layer, ukwenzela ukuba ingabangeli ukudibanisa okungahambi kakuhle phakathi kweengqimba, kwaye kuchaphazele umgangatho weemveliso.Umaleko wengubo ye-gel unokwandiswa kunyeumphezuluimat.Inkqubo yokuncamathelisa kufuneka inikele ingqalelo kwi-resin yokumiliselwa kwemicu yeglasi, okokuqala yenza ukungena kwe-resin kwindawo yonke ye-fiber bundle, kwaye emva koko wenze umoya ongaphakathi kwi-fiber bundle ithathelwe indawo ngokupheleleyo yi-resin.Kubaluleke kakhulu ukuqinisekisa ukuba umaleko wokuqala wezinto eziqiniswayo zifakwe ngokupheleleyo nge-resin kwaye zifakwe ngokusondeleyo, ngakumbi ukuba ezinye iimveliso zisetyenziswe kwiimeko eziphezulu zokushisa.Ukungena kakuhle kunye nokunyanyiswa okungahambi kakuhle kunokushiya umoya ojikeleze i-gelcoat layer, kwaye lo moya oshiywe ngasemva unokubangela amaqamza omoya ngexesha lenkqubo yokunyanga kunye nokusetyenziswa kwemveliso ngenxa yokwandiswa kwe-thermal.

Inkqubo yokubeka izandla, okokuqala kuluhlu lwejeli yedyasi okanye umphezulu wokwenza umngundo ngebrashi, i-scraper okanye i-roller yokufakela kunye nesinye isixhobo sokuncamathisela isandla ngokulungeleleneyo uqatywe umaleko weresin elungisiweyo, kwaye emva koko ubeke umaleko wezinto zokuqinisa ezisikiweyo (ezifana ne imicu diagonal, ilaphu elibhityileyo okanye umphezulu waziva, njl), ilandelwa kukwenza izixhobo ziya kuxutywa tyaba, zicinezelwe, ukuze ilingane ngokusondeleyo, kwaye ingqalelo ukukhutshelwa ngaphandle amaqamza umoya, ukuze ilaphu iglasi imiliselwe ngokupheleleyo, hayi ezimbini. okanye iileya ezininzi zokuqinisa ngexesha elinye Ukubeka.Phinda usebenze ngasentla, de kube ubukhulu obufunwa nguyilo.

Ukuba i-geometry yemveliso inzima ngakumbi, ezinye iindawo apho izinto zokuqinisa zingabekwanga, amaqamza akulula ukuba angayibandakanyi, i-scissors ingasetyenziselwa ukusika indawo kwaye iyenze ibe tyaba, kufuneka kuqatshelwe ukuba umaleko ngamnye kufuneka. Yiba yinxalenye egxadazayo yokusikwa, ukuze ungabangeli ukulahleka kwamandla.

Kwiindawo ezine-angle ethile, zinokuzaliswaifayibha yeglasi kunye ne-resin.Ukuba ezinye iindawo zemveliso zinkulu ngokwentelekiso, zinokujiya ngokufanelekileyo okanye zomelezwe kwindawo ukuhlangabezana neemfuno zokusetyenziswa.

Njengoko ulwalathiso lwefayibha yelaphu lwahlukile, amandla alo nawo ahlukile.Indlela yokubeka iilaphu lefibre yeglasiesetyenzisiweyo kunye nendlela yokubeka kufuneka yenziwe ngokweemfuno zenkqubo.

(4) ukusetyenzwa komthungo

Umaleko ofanayo wemicu ngokuqhubekayo kangangoko kunokwenzeka, ugweme ukusikwa ngokungenamkhethe okanye ukucandwa, kodwa ngenxa yobukhulu bemveliso, ukuntsonkotha kunye nezinye izizathu zokusikelwa umda ukufezekisa, inkqubo yokuncamathelisa inokuthatyathwa xa i-butt ibeka, i-lap seam iya zigxadazele de intlama ibe ngqindilili efunwa yimveliso.Xa i-gluing, i-resin ifakwe kwizixhobo ezifana neebhulashi, i-roller kunye ne-bubble rollers kunye ne-bubbles emoyeni iyakhutshwa.

Ukuba imfuno yamandla iphezulu, ukwenzela ukuba kuqinisekiswe amandla emveliso, i-lap joint kufuneka isetyenziswe phakathi kweengcezu ezimbini zengubo, ububanzi be-lap joint malunga ne-50 mm.kwangaxeshanye, umjikelo odibeneyo womaleko ngamnye kufuneka ugxadazele kangangoko kunokwenzeka.

(3)Ukubeka izandla phezuluyeintambo enqunqiweyo imats

Xa usebenzisa i-short cut evakalelwa njengezinto zokuqinisa, kungcono ukusebenzisa ubungakanani obuhlukeneyo bee-roller zokungena ukuze usebenze, kuba ii-roller zokungena zisebenza ngokukodwa ekungabandakanyi amaqamu kwi-resin.Ukuba akukho sixhobo esinjalo kwaye ukufakelwa kufuneka kwenziwe nge-brush, i-resin kufuneka isetyenziswe ngendlela ye-brush point, ngaphandle koko iifibers ziya kuxutywa kwaye zikhutshwe ukuze ukusabalalisa kungafani kwaye ubukhulu abufani.Izinto zokuqinisa ezibekwe kwikona yangaphakathi enzulu ngaphandle, ukuba i-brush okanye i-roller impregnation inzima ukuyenza ifane ngokusondeleyo, inokucolwa kwaye icinezelwe ngesandla.

Xa unikezela ngokubeka, sebenzisa i-glue roller ukufaka iglu kumphezulu wokubumba, emva koko ubeke i-mat esikiweyo ngesandla. iqhekeza kwi-mold kwaye uyigudise, emva koko sebenzisa i-glue roller kwiglu, ujikeleze ngokuphindaphindiweyo emva naphambili, ukuze iglue ye-resin intywiliselwe kwi-mat, emva koko usebenzise i-bubble roller ukucudisa iglu ngaphakathi kwi-mat. umphezulu kwaye ukhuphe amaqamza omoya, uze uncamathelise umaleko wesibini.Ukuba udibana nekona, unokukrazula i-mat ngesandla ukwenza lula ukusonga, kwaye umjikelo ophakathi kwamaqhekeza amabini omethi umalunga ne-50mm.

Iimveliso ezininzi zinokusebenzisaiimethi zomcu ezinqunqiweyokunye neglasi ifayibha ilaphu alternate layering, ezifana iinkampani Japanese uncamathisele iphenyane lokuloba kukusetyenziswa enye indlela yokuncamathelisa, kuxelwa ukuba indlela yokuvelisa iimveliso FRP kunye nokusebenza kakuhle.

(6) Inkqubo yokuncamathelisa yeemveliso ezinodonga olungqingqwa

Ubungqingqwa bemveliso obungaphantsi kwe-8 mm yeemveliso bunokubunjwa kanye, kwaye xa ubukhulu bemveliso bungaphezulu kwe-8 mm, kufuneka buhlulwe ngokubumba okuninzi, ngaphandle koko imveliso iya kuphiliswa ngenxa yokungabikho kobushushu obuphantsi obukhokelela ekutshiseni, ukujika kombala, okuchaphazela imveliso. ukusebenza kwemveliso.Kwiimveliso ezinobumba oluninzi, amaqamza kunye namaqamza enziwe emva kokunyangwa kwentlama yokuqala kufuneka ahlatywe ngomhlakulo phambi kokuqhubeka nokuncamathelisa indlela elandelayo.Ngokuqhelekileyo, kucetyiswa ukuba ubukhulu bomnye umbumba akufunekanga budlule kwi-5mm, kodwa kukwakho ukukhutshwa kobushushu obuphantsi kunye neereyini ezisezantsi eziphuhliswe ukubumba iimveliso ezityebileyo, kwaye ubukhulu bale resin bukhulu kubumba olunye.

Chongqing Dujiang Composites Co., Ltd.

Qhagamshelana nathi:

Email:marketing@frp-cqdj.com

WhatsApp: +8615823184699

Umnxeba: +86 023-67853804

Iwebhu:www.frp-cqdj.com

Ixesha lokuposa: Oct-09-2022