Ukubeka ngesandla yinkqubo elula, engabizi kwaye esebenzayo yokubumba i-FRP engadingi zixhobo zininzi kunye notyalo-mali olukhulu kwaye inokufezekisa imbuyekezo kwimali ngexesha elifutshane.

1. Ukutshiza kunye nokupeyinta ijazi lejeli

Ukuze kuphuculwe kwaye kuhonjiswe imeko yomphezulu weemveliso ze-FRP, kunyuswe ixabiso lemveliso, kwaye kuqinisekiswe ukuba umaleko wangaphakathi we-FRP awukhukuliseki kwaye kwandiswe ubomi benkonzo yemveliso, umphezulu osebenzayo wemveliso ngokubanzi wenziwa umaleko one-pigment paste (i-color paste), umxholo ophezulu we-resin womaleko wokuncamathelisa, unokuba yi-resin ecocekileyo, kodwa uphuculwe nge-surface felt. Olu maleko lubizwa ngokuba yi-gel coat layer (ekwabizwa ngokuba yi-surface layer okanye i-decoration layer). Umgangatho womaleko we-gel coat uchaphazela ngokuthe ngqo umgangatho wangaphandle wemveliso kunye nokumelana nemozulu, ukumelana namanzi kunye nokumelana nokukhukuliseka kwe-chemical media, njl. Ke ngoko, la manqaku alandelayo kufuneka aqatshelwe xa kutshizwa okanye kupeyintwa umaleko we-gel coat.

2. Ukumisela indlela yenkqubo

Indlela yenkqubo inxulumene nezinto ezahlukeneyo ezifana nomgangatho wemveliso, iindleko zemveliso kunye nomjikelo wemveliso (ukusebenza kakuhle kwemveliso). Ke ngoko, ngaphambi kokuba ulungiselele imveliso, kuyimfuneko ukuba ube nokuqonda okubanzi kweemeko zobugcisa (imeko-bume, ubushushu, iphakathi, umthwalo ……, njl.njl.), ulwakhiwo lwemveliso, ubungakanani bemveliso kunye neemeko zokwakha xa kusetyenziswa imveliso, kwaye emva kohlalutyo nophando, ukuze kuchongwe iskimu senkqubo yokubumba, ngokubanzi, kufuneka kuqwalaselwe ezi zinto zilandelayo.

3. Umxholo ophambili woyilo lwenkqubo

(1) Ngokweemfuno zobugcisa zemveliso ukukhetha izixhobo ezifanelekileyo (izinto zokuqinisa, izinto zokwakha kunye nezinye izinto ezincedisayo, njl.njl.). Ekukhetheni izinto eziluhlaza, ezi zinto zilandelayo ziqwalaselwa kakhulu.

① Nokuba imveliso idibana ne-asidi kunye ne-alkaline media, uhlobo lwe-media, uxinaniso, ubushushu bokusetyenziswa, ixesha lokudibana, njl.njl.

② Nokuba kukho iimfuno zokusebenza ezifana nokudluliselwa kokukhanya, into ethintela ilangatye, njl.

③Ngokuphathelele iimpawu zoomatshini, nokuba ngumthwalo oguqukayo okanye ongashukumiyo.

④Nokuba kukho okanye akukho ukuthintela ukuvuza kunye nezinye iimfuno ezikhethekileyo.

(2) Misela isakhiwo kunye nezinto ezisetyenziswayo xa kusenziwa isikhunta.

(3) Ukukhetha iarhente yokukhulula.

(4) Misela indlela yokulinganisa i-resin kunye nenkqubo yokulungisa.

(5) Ngokweemfuno zobukhulu bemveliso kunye namandla ayo, misela uluhlu lwezinto zokuqinisa, iinkcukacha, inani leeleya kunye nendlela yokubeka iileya.

(6) Ukulungiswa kweenkqubo zenkqubo yokubumba.

4. Inkqubo yokuncamathisela umaleko weplastiki oqinisiweyo wefayibha yeglasi

Ukubeka isandla yinkqubo ebalulekileyo yokubumba ngesandla, kufuneka isebenze kakuhle ukuze kufezekiswe umxholo we-resin okhawulezayo, ochanekileyo, olinganayo, kungabikho maqamza acacileyo, kungabikho kumila okubi, kungabikho monakalo kwifayibha kunye nomphezulu wemveliso othe tyaba, ukuqinisekisa umgangatho weemveliso. Ke ngoko, nangona umsebenzi wokuncamathisela ulula, akulula kakhulu ukwenza iimveliso zibe ntle, kwaye kufuneka zithathwe nzulu.

(1) Ulawulo lokutyeba

Ifayibha yeglasiUlawulo lobukhulu beemveliso zeplastiki eziqinisiweyo, luyilo lwenkqubo yokuncamathisela ngesandla kunye nenkqubo yemveliso eya kudibana neengxaki zobugcisa, xa sisazi ubukhulu obufunekayo bemveliso, kuyimfuneko ukubala ukuze kuchongwe i-resin, umxholo wokuzalisa kunye nezinto zokuqinisa ezisetyenzisiweyo kwiinkcukacha, inani leeleya. Emva koko bala ubukhulu bayo obuqikelelweyo ngokwefomula elandelayo.

(2) Ukubalwa komthamo weresin

Idosi ye-resin ye-FRP yiparameter ebalulekileyo yenkqubo, enokubalwa ngeendlela ezimbini ezilandelayo.

Ukubala ngokwemigaqo yokuzalisa isithuba, ifomula yokubala ubungakanani beresin, yazi kuphela ubunzima bendawo yelaphu leglasi kunye nobukhulu obulinganayo (umalekoiglasiifayibhailaphu ilingana nobukhulu bemveliso), ungabala ubungakanani be-resin equlethwe kwi-FRP

I-B ibalwe ngokubala kuqala ubunzima bemveliso kunye nokumisela umxholo wepesenti yobunzima befayibha yeglasi.

(3)Iglasiifayibhainkqubo yokuncamathisela ilaphu

Iimveliso ezine-gelcoat layer, i-gelcoat ayinakuxutywa nokungcola, incamathiselwe ngaphambi kwenkqubo kufuneka ithintele ungcoliseko phakathi kwe-gelcoat layer kunye ne-backward layer, ukuze ingabangela ukudibana okubi phakathi kwe-layer, kwaye ichaphazele umgangatho weemveliso. I-gel coat layer inokuphuculwa ngeumphezuluimathiInkqubo yokuncamathisela kufuneka iqwalasele ukufakwa kwe-resin kwiifayibha zeglasi, kuqala yenze ukungena kwe-resin kumphezulu wonke we-fiber bundle, ize emva koko yenze umoya ongaphakathi kwi-fiber bundle uthatyathelwe indawo yi-resin ngokupheleleyo. Kubaluleke kakhulu ukuqinisekisa ukuba umaleko wokuqala wezinto zokuqinisa ufakwe i-resin ngokupheleleyo kwaye ufakwe ngokusondeleyo, ngakumbi kwezinye iimveliso ezisetyenziselwa kwiimeko zobushushu obuphezulu. Ukufunxwa okubi kunye nokulamina okubi kunokushiya umoya ujikeleze umaleko we-gelcoat, kwaye lo moya ushiyekileyo unokubangela amaqamza omoya ngexesha lenkqubo yokunyanga nokusetyenziswa kwemveliso ngenxa yokwanda kobushushu.

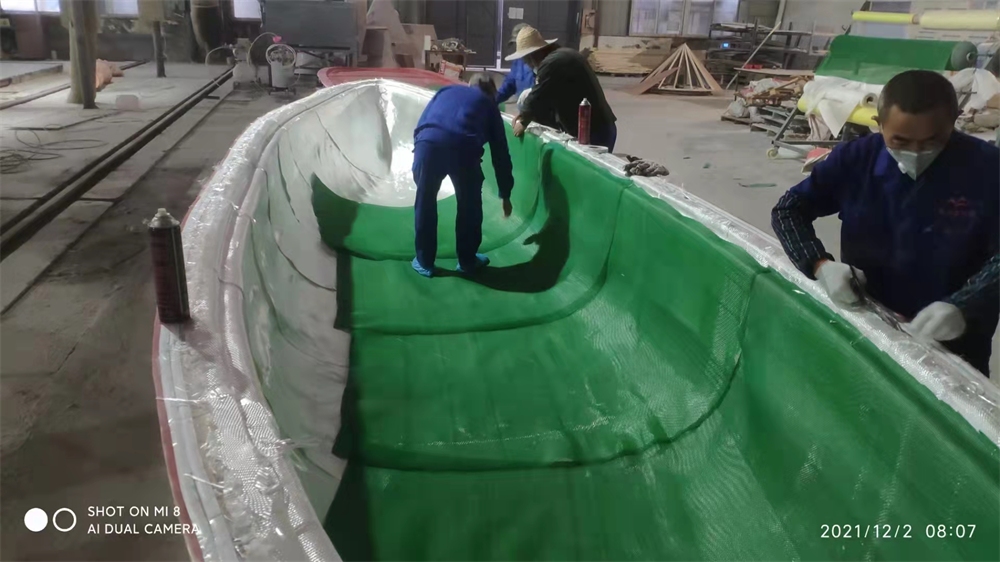

Inkqubo yokubeka ngesandla, kuqala kumaleko wejazi lejeli okanye umphezulu wokwenza umngundo ngebrashi, i-scraper okanye i-impregnation roller kunye nesinye isixhobo sokuncamathisela ngesandla esigqunywe ngokulinganayo ngomaleko we-resin elungisiweyo, uze emva koko ubeke umaleko wezinto zokuqinisa ezisikiweyo (ezifana nemicu ethe tyaba, ilaphu elincinci okanye i-surface felt, njl.njl.), kulandele izixhobo zokwakha eziya kuxutywa zithe tyaba, zicinezelwe, ukuze zilingane kakuhle, kwaye zinike ingqalelo ekukhutshweni kwamaqamza omoya, ukuze ilaphu leglasi lifakwe ngokupheleleyo, kungabi ngamaleko amabini okanye ngaphezulu ezinto zokuqinisa ngexesha elinye. Ukubeka. Phinda lo msebenzi ungasentla, ude ube bubukhulu obufunekayo kuyilo.

Ukuba ijiyometri yemveliso iyinkimbinkimbi ngakumbi, kwezinye iindawo apho izinto zokuqinisa zingabekwanga zithe tyaba, amaqamza akulula ukuwakhupha, izikere zingasetyenziselwa ukusika indawo kwaye ziyenze ibe tyaba, kufuneka kuqatshelwe ukuba umaleko ngamnye kufuneka ube ziinxalenye ezijikelezileyo zokusika, ukuze ungabangeli ukulahleka kwamandla.

Kwiindawo ezineekona ezithile, zingazaliswaifayibha yeglasi kunye ne-resin. Ukuba ezinye iindawo zemveliso zinkulu ngokwentelekiso, zingaqiniswa okanye ziqiniswe ngokufanelekileyo kwindawo ukuze kuhlangatyezwane neemfuno zokusetyenziswa.

Njengoko icala lefayibha yelaphu lahlukile, namandla ayo ahlukile. Indlela yokubeka ifayibha yelaphuilaphu lefayibha yeglasiisetyenzisiwe kwaye indlela yokubeka kufuneka yenziwe ngokweemfuno zenkqubo.

(4) ukucubungula umthungo welaphu

Umaleko ofanayo weefayibha oqhubekayo kangangoko kunokwenzeka, kuphephe ukusikwa okanye ukuxhuzulwa ngokungacwangciswanga, kodwa ngenxa yobukhulu bemveliso, ubunzima kunye nezinye izizathu zemida ekufuneka ifezekiswe, inkqubo yokuncamathisela ingathathwa xa kubekwa i-butt, umthungo we-lap kufuneka udityaniswe de kube yintlama ukuya kubukhulu obufunekayo kwimveliso. Xa incamathiselwa, i-resin ifakwa izixhobo ezifana neebhrashi, iirola kunye neerola zebhamuza kwaye amaqamza omoya ayakhutshwa.

Ukuba imfuneko yamandla iphezulu, ukuqinisekisa amandla emveliso, i-lap joint kufuneka isetyenziswe phakathi kweziqwenga ezibini zelaphu, ububanzi be-lap joint bumalunga ne-50 mm. Kwangaxeshanye, i-lap joint yomaleko ngamnye kufuneka ijikeleziswe kangangoko kunokwenzeka.

(3)Ukubeka isandla phezuluyeumsonto oqoshiweyo imathis

Xa usebenzisa i-short cut felt njengezinto zokuqinisa, kungcono ukusebenzisa ubungakanani obahlukeneyo bee-impregnation rollers ukuze usebenze, kuba ii-impregnation rollers zisebenza kakuhle ekukhupheni amaqamza kwi-resin. Ukuba akukho sixhobo sinjalo kwaye i-impregnation kufuneka yenziwe ngebrashi, i-resin kufuneka isetyenziswe ngendlela ye-point brush, kungenjalo iifayibha ziya konakala kwaye zisuswe ukuze usasazo lungalingani kwaye ubukhulu bungafani. Izinto zokuqinisa ezibekwe kwikona enzulu yangaphakathi ngaphandle, ukuba i-brush okanye i-impregnation roller kunzima ukuyenza ilingane kakuhle, inokulungiswa kwaye icinezelwe ngesandla.

Xa uhambisa izinto ezibekwe phantsi, sebenzisa i-glue roller ukuze ufake iglu kumphezulu we-mold, uze uyibeke ngesandla imathi esikiweyo. Yifake kwisikhunta uze uyilungise, uze usebenzise i-glue roller kwi-glue, uyijike ngokuphindaphindiweyo, ukuze i-resin glue ingene kwi-mat, uze usebenzise i-glue bubble roller ukuze ucinezele i-glue ngaphakathi kwi-mat phezu komphezulu uze ukhuphe amaqamza omoya, uze uncamathisele umaleko wesibini. Ukuba udibana nekona, ungayikrazula i-mat ngesandla ukuze kube lula ukuyisonga, kwaye umgama phakathi kweziqwenga ezibini ze-mat ungange-50mm.

Iimveliso ezininzi zingasebenzisaiimathi ezinqunqiweyo zemicukunye nelaphu leglasi elifana nelaphu, njengeenkampani zaseJapan ezincamathisela isikhephe sokuloba, kusetyenziswe indlela yokuncamathisela enye, kuxelwa ukuba indlela yokuvelisa iimveliso ze-FRP isebenza kakuhle.

(6) Inkqubo yokuncamathisela yeemveliso ezibiyelweyo

Ubukhulu bemveliso obungaphantsi kwe-8 mm bunokwenziwa kube kanye, kwaye xa ubukhulu bemveliso bungaphezulu kwe-8 mm, kufuneka bahlulwe babe ziimolding ezininzi, kungenjalo imveliso iya kunyangwa ngenxa yokungatshatyalali kakuhle kobushushu okukhokelela ekutshiseni, ekutshintsheni kombala, okuchaphazela ukusebenza kwemveliso. Kwiimveliso ezinemolding ezininzi, ii-burrs kunye namaqamza enziwe emva kokulungiswa kwepeyinti yokuqala kufuneka zisuswe ngefosholo ngaphambi kokuba ziqhubeke nokuncamathisela ipavumente elandelayo. Ngokubanzi, kucetyiswa ukuba ubukhulu bemolding enye bungadluli kwi-5mm, kodwa kukwakho nokukhululwa kobushushu obuphantsi kunye neeresinsi ezinciphayo eziphuhlisweyo zokubumba iimveliso ezityebileyo, kwaye ubukhulu bale resin bukhulu kwimolding enye.

IChongqing Dujiang Composites Co., Ltd.

Qhagamshelana nathi:

Email:marketing@frp-cqdj.com

I-WhatsApp:+8615823184699

Umnxeba: +86 023-67853804

Iwebhu:www.frp-cqdj.com

Ixesha lokuthumela: Okthobha-09-2022