Intshayelelo

Iglasi yefayibha sisixhobo esinokusetyenziswa ngeendlela ezahlukeneyo esisetyenziswa kakhulu kumashishini afana nokwakha, iimoto, ezolwandle, kunye neenqwelo-moya ngenxa yamandla aso, ukuqina, kunye neempawu ezikhaphukhaphu. Iindlela ezimbini eziqhelekileyo zokuqinisa i-fiberglass zeziimathi yentambo eqoshiweyo (CSM) kunyeilaphu le-fiberglass elukiweyoNangona zombini zisebenza njengokuqinisa izinto ezidityanisiweyo, zineempawu ezahlukileyo ezenza zilungele ukusetyenziswa ezahlukeneyo.

Kweli nqaku, siza kuhlola umahluko ophambili phakathi kwentambo eqoshiweyo kunye ne-fiberglass elukiweyo, kuquka iinkqubo zokwenziwa kwazo, iimpawu zoomatshini, ukusetyenziswa kwazo, kunye neenzuzo.

1. Inkqubo yoMveliso

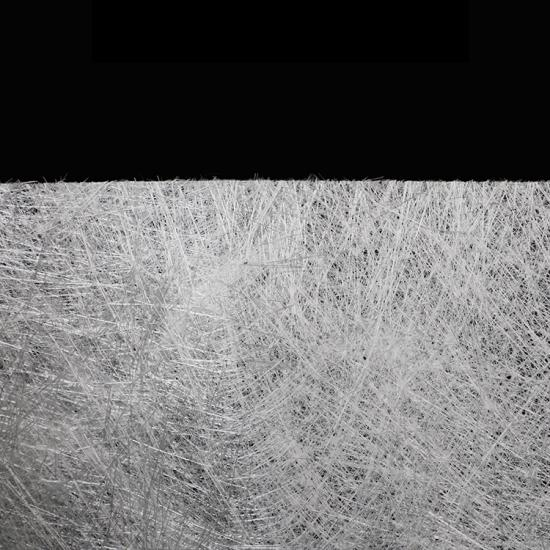

I-Strand Mat eqoshiweyo (CSM)

Yenziwe ngeefayibha zeglasi ezimfutshane ezisasazwa ngokungacwangciswanga (ngesiqhelo ubude buyi-1-2 intshi) ezidityaniswe kunye nesihlanganisi esinyibilikayo se-resin.

Yenziwa ngokusika imicu yeglasi eqhubekayo ize isasazwe kwibhanti yokuhambisa, apho kufakwa khona i-binder ukuze ibambeke kunye.

Ifumaneka ngobunzima obahlukeneyo (umz., 1 oz/ft² ukuya kwi-3 oz/ft²) kunye nobukhulu.

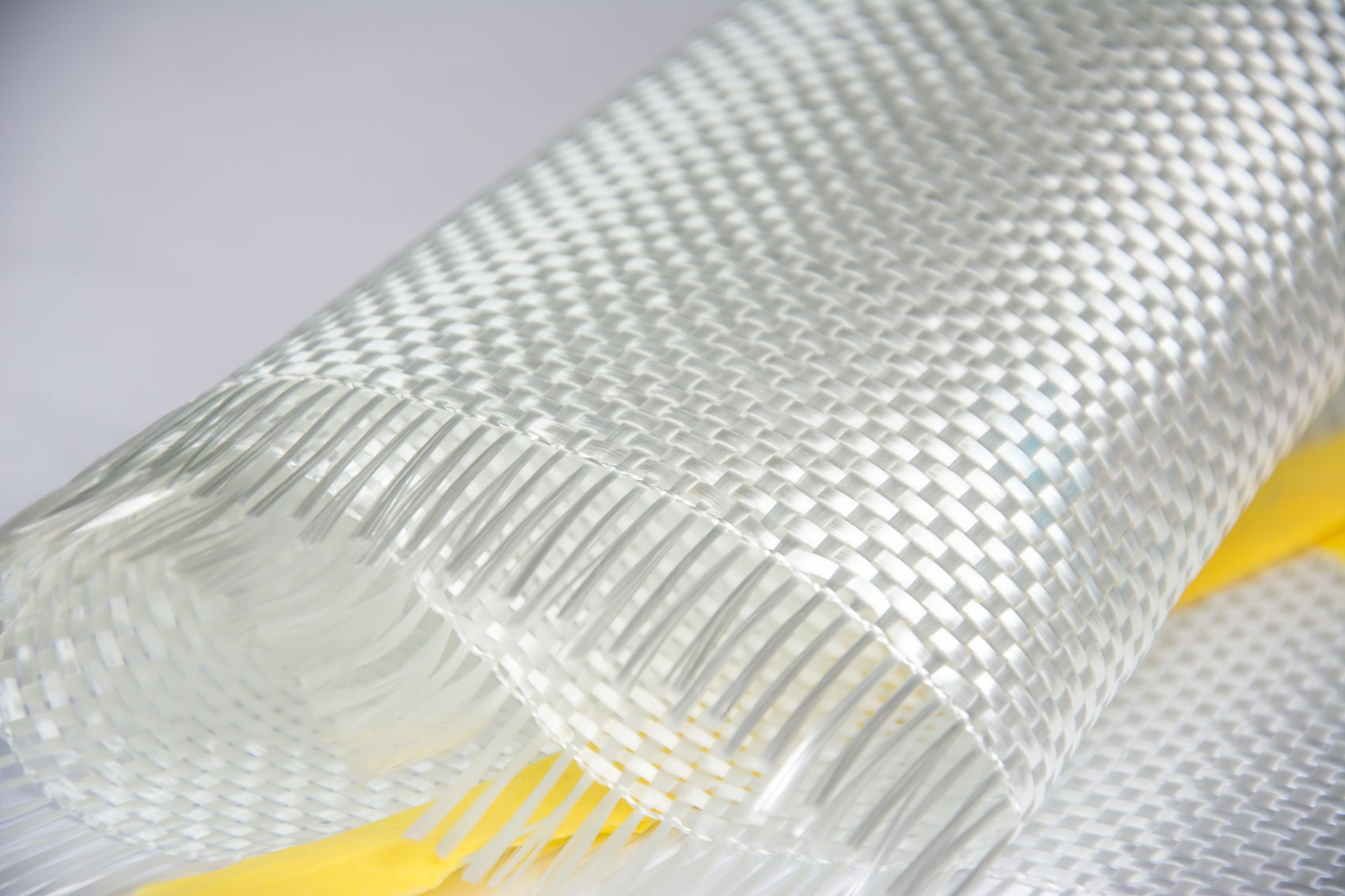

Ilaphu leFiberglass elukiweyo

Yenziwe ngokuluka imicu yefayibha yeglasi eqhubekayo ibe yipatheni efanayo (umz., i-plain weave, i-twill weave, okanye i-satin weave).

Inkqubo yokwaluka idala isakhiwo esomeleleyo, esifana negridi kunye neefayibha ezisebenza kwi-0° kunye nama-90° izikhombisi-ndlela, ezinika amandla okubhekisa kwicala.

Iza ngeendlela ezahlukeneyo zobunzima kunye neendlela zokuluka, nto leyo echaphazela ukuguquguquka kunye namandla.

Umahluko oPhambili:

I-CSM ayihambelani ngqo (isotropic) ngenxa yokujonga i-fiber ngendlela engacwangciswanga, ngelixai-fiberglass ukuzulazula okulukiweyo ibhekiselele kwicala elithile (i-anisotropic) ngenxa yokwakheka kwayo okuntsonkothileyo.

2.Iipropati zoomatshini

| Ipropati | I-Crand Mat eqoshiweyo (CSM) | Ilaphu leFiberglass elukiweyo |

| Amandla | Amandla okuxinana aphantsi ngenxa yeefayibha ezingahleliweyo | Amandla aphezulu okuxinana ngenxa yeefayibha ezihambelanayo |

| Ukuqina | Ayiqinanga kangako, iguquguquka ngakumbi | Iqinile ngakumbi, igcina imilo ingcono |

| Ukumelana neempembelelo | Ilungile (iifayibha zifunxa amandla ngokungacwangciswanga) | Igqwesile (iifayibha zisasaza umthwalo ngokufanelekileyo) |

| Ukuhambelana | Kulula ukuyibumba ibe ziimo ezintsonkothileyo | Ayiguquguquki kangako, kunzima ukuyigubungela phezu kwamagophe |

| Ukufunxwa kweResin | Ukufunxwa kwe-resin ephezulu (40-50%) | Ukufunxwa kwe-resin okuphantsi (30-40%) |

Kutheni Kubalulekile:

I-CSM ilungele iiprojekthi ezifuna ukubumba okulula kunye namandla afanayo kuzo zonke iindlela, njengeenqanawa zeenqanawa okanye iindawo zokuhlambela.

Figlasi ye-iberglass ukuzulazula okulukiweyo Ingcono kwizicelo ezinamandla aphezulu njengeephaneli zeemoto okanye izinto zokwakha apho kufuneka uqinisekiso olubhekiselele kwicala.

3. Izicelo kwiiShishini ezahlukeneyo

I-Strand Mat eqoshiweyo (CSM) Ukusetyenziswa:

✔Ishishini leeLwandle–Iinqanawa, iidekhi (ezilungele ukuthintela amanzi).

✔Iimoto–Iindawo ezingezizo ezakhiweyo njengeephaneli zangaphakathi.

✔Ulwakhiwo–Uphahla, iibhafu, kunye neendawo zokuhlamba.

✔Umsebenzi Wokulungisa–Kulula ukuyifaka kwiindlela ezahlukeneyo ukuze kulungiswe ngokukhawuleza.

Ukusetyenziswa kweLaphu leFiberglass elukiweyo:

✔Inqwelo-moya–Izixhobo ezikhaphukhaphu nezinamandla aphezulu.

✔Iimoto–Iiphaneli zomzimba, ii-spoilers (zifuna ukuqina okuphezulu).

✔Amandla oMoya–Iiblade zeTurbine (zifuna amandla okubhekisa kwicala).

✔Izixhobo zemidlalo–Iifreyimu zebhayisekile, iintonga zehoki.

Into ebalulekileyo ekufuneka uyithathe:

I-CSM yeyona ilungileyo ekuqiniseni ngexabiso eliphantsi, ngokwenjongo ngokubanzi.

I-fiberglass elukiweyo ikhethwa kakhulu kwizicelo ezisebenza kakuhle nezithwala umthwalo.

4. Ukulula kokusetyenziswa nokuphathwa

I-Strand Mat eqoshiweyo (CSM)

✅Kulula ukusika nokubumba–Inganqunyulwa ngesikere.

✅Ihambelana kakuhle neegophe–Ilungele iimbombo ezintsonkothileyo.

✅Ifuna i-resin engakumbi–Ifunxa ulwelo oluninzi, nto leyo enyusa iindleko zezinto.

Ilaphu leFiberglass elukiweyo

✅Iqinile kodwa ayiguquguquki kangako–Ifuna ukusika ngokuchanekileyo.

✅Kungcono kwiindawo ezithe tyaba okanye ezigobileyo kancinci–Kunzima ukujika phezu kwamagophe abukhali.

✅Ukufunxwa kwe-resin okuncinci–Ixabiso liphantsi ngakumbi kwiiprojekthi ezinkulu.

Ingcebiso yobungcali:

Abaqalayo badla ngokuthanda i-CSM kuba'ixolela kwaye kulula ukusebenza nayo.

Iingcali zikhetha i-fiberglass ukuzulazula okulukiweyo ukuze kube nokuchaneka kunye namandla.

5.Uthelekiso lweendleko

| I-Factor | I-Crand Mat eqoshiweyo (CSM) | Ilaphu leFiberglass elukiweyo |

| Ixabiso lezinto eziphathekayo | Ephantsi (ukwenziwa okulula) | Iphezulu (ukuluka kongeza iindleko) |

| Ukusetyenziswa kweResin | Phezulu (kufuneka i-resin engaphezulu) | Ezantsi (i-resin encinci ayifuneki) |

| Iindleko Zabasebenzi | Kukhawuleza ukuyifaka (kulula ukuyiphatha) | Kufuneka isakhono esingakumbi (ulungelelwaniso oluchanekileyo) |

Yeyiphi Enoqoqosho Ngakumbi?

I-CSM ixabisa kancinci ekuqaleni kodwa ingadinga i-resin engakumbi.

Figlasi ye-iberglass ukuzulazula okulukiweyo inexabiso eliphezulu lokuqala kodwa inika umlinganiselo ongcono wokuqina nobunzima.

6. Yeyiphi Ofanele Uyikhethe?

Ixesha lokusebenzisaI-Strand Mat eqoshiweyo (CSM):

Kufuneka ulungelelanise ngokukhawuleza nangokulula iimilo ezintsonkothileyo.

Ukusebenza kwiiprojekthi ezingezizo ezakhiwo, ezobuhle, okanye ezokulungisa.

Uhlahlo-lwabiwo mali luyinto exhalabisayo.

Ixesha Lokusebenzisa Ilaphu Le-Fiberglass Elilukiweyo:

Kufuna amandla aphezulu kunye nokuqina.

Ukusebenza kwizakhiwo ezithwala imithwalo (umz., iinxalenye zeemoto, iinxalenye zeenqwelo-moya).

Kufuneka ugqitywe ngcono umphezulu (ilaphu elilukiweyo lishiya ugqitywe kakuhle).

Isiphelo

Zombiniimathi yentambo eqoshiweyo (CSM) kwayeilaphu le-fiberglass elukiweyo zizinto ezifunekayo zokuqinisa kwimveliso edibeneyo, kodwa zisebenza ngeenjongo ezahlukeneyo.

I-CSMiyafikeleleka, kulula ukuyisebenzisa, kwaye ilungele ukuqinisa ngokubanzi.

I-fiberglass elukiweyo inamandla, ihlala ixesha elide, kwaye ifanelekile kwizicelo ezisebenza kakuhle.

Ukuqonda umahluko phakathi kwabo kunceda ekukhetheni izinto ezifanelekileyo zeprojekthi yakho, ukuqinisekisa ukusebenza kakuhle kunye nokonga imali.

Ixesha leposi: Julayi-04-2025