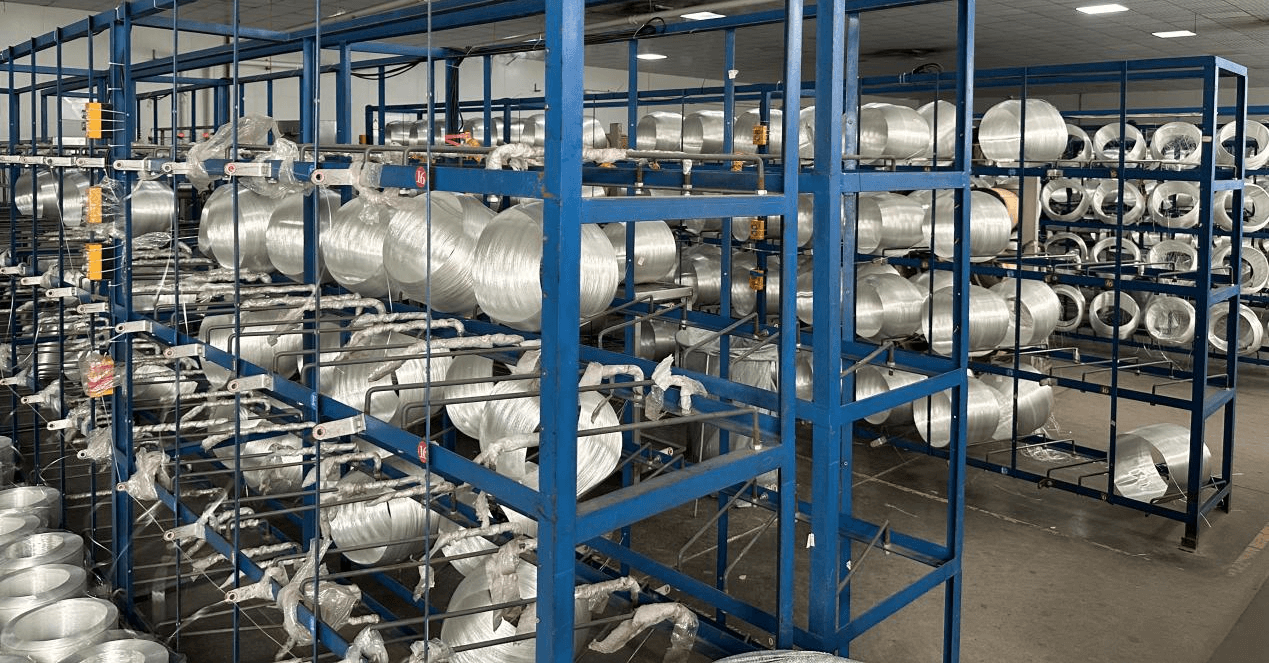

Kwihlabathi lokuvelisa izinto ezidityanisiweyo, kuchithwa izixhobo ezibalulekileyo ukuphucula i-resin chemistry, ukuphucula isantya se-pultrusion, kunye nokuphucula umlinganiselo we-fiber-to-resin. Nangona kunjalo, kukho into ebalulekileyo edla ngokungajongwa de umgca wemveliso uyeke okanye iqela leenxalenye ezigqityiweyo lingaphumeleli kuvavanyo loxinzelelo:indawo yokugcina izintoukuzulazula kwefiberglass.

Ukuhambahamba nge-fiberglassayisiyonto ingenamsebenzi. Yinto eyenziwe ngobuchule obuphezulu egqunywe "ngobukhulu" beekhemikhali ezintsonkothileyo ezisebenza njengonxibelelwano phakathi kweglasi engaphiliyo kunye ne-resin yendalo. Le khemikhali inobuthathaka, kwaye ukonakala kwayo ngexesha lokugcina kunokukhokelela ekusileleni okukhulu kwimilo yesakhiwo.

Kule khokelo, sihlola indlela amaqondo obushushu, ukufuma, kunye neendlela zokugcina izinto ezibonakalayo ezilawula ngayo ukusebenza kwezixhobo zakho zokuqinisa.

Utshaba Olungabonakaliyo: Umswakama kunye neHydrolysis

Eyona ngozi ibalulekileyo yokugcina izintoukuzulazula kwefiberglassifumile. Ifayibha yeglasi ithanda ukufunxa amanzi ngokwemvelo (itsala amanzi). Nangona imicu yeglasi ngokwayo ihlala ixesha elide,inkqubo yokulinganisa—ibhulorho yeekhemikhali evumela i-resin ukuba “iphume imanzi” ize inamathele kwifayibha—inokuchaphazeleka lulai-hydrolysis.

Niniifayibha yeglasiukuhambahambaigcinwa kwindawo enomswakama ophezulu:

Ukuncipha kobukhulu:Ukufuma kuyawaphula amaqhina eekhemikhali ngaphakathi kobukhulu, nto leyo eyenza ukuba kungasebenzi kakuhle ekukhuthazeni ukunamathela.

Ukumanzisa Okubi:Ngexesha lokuveliswa, i-resin ayiphumeleli ukungena ngokupheleleyo kwi-fiber bundle, nto leyo ekhokelela "kwiindawo ezomileyo" kunye nokungafumaneki kwi-composite yokugqibela.

Isenzo seCapillary:Ukuba iziphelo zeebobbins ziyabonakala, umswakama ungatsalwa nzulu kwiphakheji ngesenzo se-capillary, nto leyo ebangela ukusebenza okungahambelaniyo kulo lonke umqulu.

Ukuguquguquka kobushushu kunye nokufuduka kobungakanani

Ngelixaifayibha yeglasiinokumelana nobushushu obuphezulu, kodwa ubungakanani bezinto eziphilayo abunawo. Ukuba indawo yokugcina impahla itshiswa kakhulu (ngaphezu kwama-35°C/95°F), into eyaziwa ngokuba yiukufuduka kobungakananiI-chemical coating isenokushukuma kancinci, ihlangane ezantsi kwe-bobbin okanye idale "amabala anamathelayo."

Ngokwahlukileyo koko, ukugcina ulwandle luhambahamba phantsi kweemeko ezibandayo uze emva koko ulufudusele kumgangatho wemveliso ofudumeleyo kukhokelela ekubeniukufumaOku kuqokelelana ngokukhawuleza komswakama kumphezulu wefayibha yeyona nto iphambili ekuqhekekeni kwemibhobho yenxeba le-filament kunye nemithambo yoxinzelelo.

Ukuthelekisa: Iimeko zokugcina ezifanelekileyo xa kuthelekiswa nezingaphantsi komgangatho

Ukunceda iqela lakho lolawulo lomgangatho lihlole izakhiwo zakho, jonga le theyibhile ilandelayo ukuze ufumane imilinganiselo esemgangathweni yoshishino.

Imigangatho Yokugcina Izinto Ezijikelezayo ZeFiberglass

| Ipharamitha | Imeko efanelekileyo (Uqheliso oluBalaseleyo) | Imeko Engaphantsi Komgangatho (Umngcipheko Omkhulu) | Impembelelo kwiNtsebenzo |

| Ubushushu | 5°C ukuya kwi-35°C (Izinzile) | Ngaphantsi kwe-0°C okanye ngaphezulu kwama-40°C | Ukulinganisa ukufuduka, iifayibha ezibuthathaka, okanye ukufuma. |

| Ubuntu bezizalwane | 35% ukuya kuma-65% | Ngaphezulu kwe-75% | Ukutsalwa kwe-hydrolysis yobukhulu, ukudibana kwe-resin-to-fiber okungahambi kakuhle. |

| Ukuqhelana | Iiyure ezingama-24–48 kwindawo yokusebenzela ngaphambi kokuba uyisebenzise. | Ukusetyenziswa ngqo kwindawo yokugcina ebandayo. | Ukuqhekeka okuncinci kwi-resin matrix ngenxa yokufuma. |

| Ukubeka inqwaba | Iipalethi zokuqala; ubuninzi obuphezulu buzi-2 (ukuba ziyilwe). | Iibobbins ezikhululekileyo; ukuphakama okugqithisileyo kokuqokelelana. | Ukuguquka komzimba kwee-bobbins; iingxaki zoxinzelelo. |

| Ukukhanya Okukhanyayo | Indawo emnyama okanye ephantsi kwe-UV. | Ukukhanya kwelanga ngqo (kufutshane neefestile). | Ukonakala kwe-UV kwiikhemikhali zokupakisha kunye nobungakanani. |

Ukunyaniseka komzimba: Iingxaki zokuxinana kunye noxinzelelo

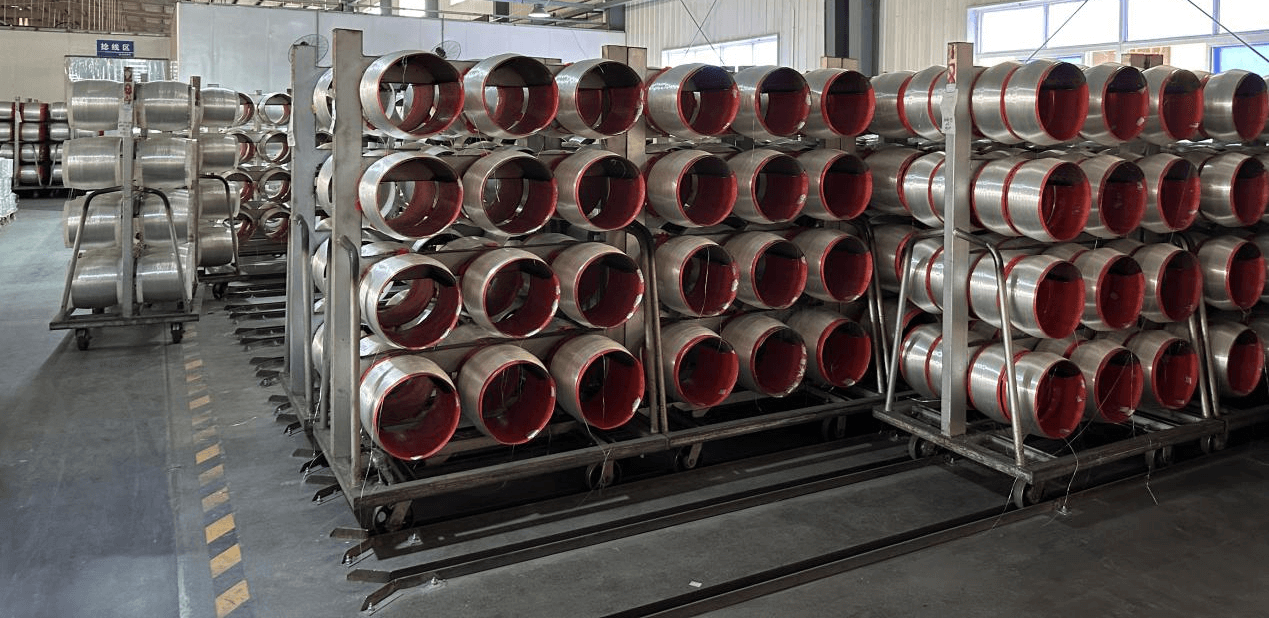

Ukuhambahamba nge-fiberglassidla ngokubotshelelwa kwiibobbins ngoxinzelelo oluchanekileyo. Ukuba ezi bobbins zigcinwa ngendlela engafanelekanga—njengokubekwa ngokuthe tye ngaphandle kwenkxaso okanye ukutyunyuzwa phantsi kobunzima obugqithisileyo—ijometri yangaphakathi yephakheji iyatshintsha.

Utshintsho kwiingcinezelo:Iibobbins ezityumkileyo zikhokelela "ekuhlawuleni" okungalinganiyo ngexesha lokuqhekeka okanye ukujijwa kwefilament. Oku kubangela ukuba ezinye iifayibha zibe lukhuni kunezinye, nto leyo edala uxinzelelo lwangaphakathi kwinxalenye egqityiweyo enokukhokelela ekugobeni okanye ekusileleni kwangaphambi kwexesha.

Ukungakhululeki kunye nokuqhekeka:Xa iibobbins zingqubana okanye zirhuqwa kumgangatho wendlu yokugcina impahla orhabaxa, iileya zangaphandle zeglasi ziyamoshakala. Ezi filaments ziqhekekileyo zenza "i-fuzz" kumgca wemveliso, nto leyo enokuthi ivale izikhokelo kwaye ingcolise ibhafu yeresin.

Indima Yokupakisha: Kutheni "I-Original" Ingcono Kakhulu

I-fiberglass esemgangathweni ophezulu ehambahambayoidla ngokuhanjiswa nge-UV-stabilized shrink wrap kunye neepakethe ze-desiccant. Impazamo eqhelekileyo kwiindawo zokwenza imveliso kukususa le paki ngaphambi kwexesha.

Ingubo yokuqala yenza imisebenzi emithathu ebalulekileyo:

Isithintelo sokufuma:Isebenza njengekhaka eliphambili lokukhusela ukufuma okungqongileyo.

Ukuthintela uthuli:Izinto ezincinci (uthuli, uthuli lwesarha, okanye iziqwenga zesinyithi) ezivela kwindawo yefektri zinokuphazamisana nobudlelwane beekhemikhali phakathi kweglasi kunye neresin.

Ukuthintela:Ithintela ukuzulazula “ekutsibeni” okanye ekuweni kwi-bobbin ngexesha lokuphathwa.

Iindlela ezi-5 ezilungileyo zokugcina umgangatho wokuhambahamba

Ukuqinisekisa ukuba izinto zakho zisebenza kanye njengoko kuchaziwe ngumvelisi, sebenzisa ezi ndlela zintlanu zokugcina impahla:

Oqalayo Ukungena, Oqalayo Ukuphuma (FIFO): Ukuhambahamba nge-fiberglassIhlala ixesha elide, idla ngokuba ziinyanga ezi-6 ukuya kwezili-12. Qinisekisa ukuba imfuyo endala isetyenziswa kuqala ukuthintela ukuguga kobukhulu bayo.

Umthetho weeYure ezingama-24:Soloko uzisa izinto eziphuma kwindawo yokugcina impahla kwiholo yemveliso ubuncinane iiyure ezingama-24 ngaphambi kokuba uyisebenzise. Oku kuvumela ukuba izinto zifikelele "kwi-thermal equilibrium," nto leyo ethintela ukufuma xa iphakheji ivuliwe.

Indawo yokugcina ephezulu:Ungaze ugcine iipalethi ezijikelezayo ngqo kumgangatho wesamente, ezinokususa umswakama. Sebenzisa iirakhi okanye iipalethi zomthi.

IiBobbins eziNcinci zeSeal:Ukuba i-bobbin ayisetyenziswanga ngokupheleleyo, musa ukuyishiya ingabonakali kumatshini. Yisonge kwakhona ngeplastiki ngaphambi kokuba uyibuyisele kwindawo yokugcina.

Ukujonga ngeeHygrometers:Faka izixhobo zokujonga ubushushu kunye nokufuma kwedijithali kwiindawo zakho zokugcina. Olu lwazi lubaluleke kakhulu xa usombulula ingxaki yokunyuka ngequbuliso kweziphene zemveliso.

Isiphelo: Ukukhusela utyalo-mali lwakho

Ukuhambahamba nge-fiberglasssisixhobo esisebenza kakuhle kakhulu, kodwa ukusebenza kwaso kuyabuthathaka de sinyangeke ngaphakathi kwe-resin matrix. Ngokuphatha iimeko zokugcina ngononophelo olufanayo nemigangatho yakho yokuvelisa, unganciphisa kakhulu amazinga enkunkuma, uphucule ukuhambelana kwenxalenye, kwaye uqinisekise ukuqina kwexesha elide kweemveliso zakho ezidityanisiweyo.

IChongqing Dujiang Composites Co., Ltd.

Qhagamshelana nathi:

Iwebhu: www.frp-cqdj.com/www.cqfiberglass.com/www.cqfrp.ru/www.cqdjfrp.com

I-imeyile:info@cqfiberglass.com/marketing@frp-cqdj.com /marketing01@frp-cqdj.com

I-WhatsApp:+8615823184699

Ucingo:+86-023-67853804

Ixesha lokuthumela: Jan-09-2026