Ifayibha yekhabhoni yimpahla yefayibha enomxholo wekhabhoni ongaphezulu kwama-95%. Ineempawu ezintle kakhulu zoomatshini, iikhemikhali, umbane kunye nezinye. "Ngukumkani wezinto ezintsha" kwaye yinto yobuchule engenazo kuphuhliso lomkhosi nolwabemi. Yaziwa ngokuba yi "Black Gold".

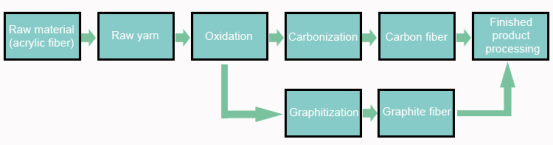

Umgca wemveliso ye-carbon fiber ngolu hlobo lulandelayo:

Yenziwa njani i-carbon fiber ebhityileyo?

Iteknoloji yenkqubo yokuvelisa ifayibha yekhabhoni iphuhlile kwaye ikhulile ukuza kuthi ga ngoku. Ngophuhliso oluqhubekayo lwezinto ezidityanisiweyo zefayibha yekhabhoni, ithandwa ngakumbi kuzo zonke iinkalo zobomi, ingakumbi ukukhula okunamandla kweenqwelo moya, iimoto, oololiwe, iiblayidi zamandla omoya, njl.njl. kunye nefuthe layo eliqhubayo, uphuhliso lweshishini lefayibha yekhabhoni. Amathemba abanzi nangakumbi.

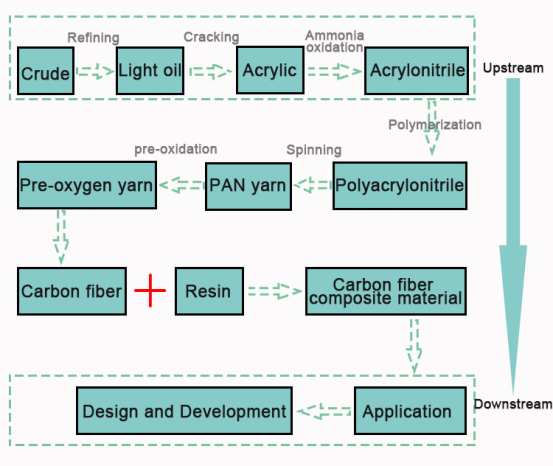

Ishishini le-carbon fiber linokwahlulwahlulwa libe phezulu nasezantsi. Eliphezulu lidla ngokubhekisa ekuvelisweni kwezinto ezithile ze-carbon fiber; elisezantsi lidla ngokubhekisa ekuvelisweni kwezinto ezisetyenziswa yi-carbon fiber. Iinkampani eziphakathi kwe-upstream ne-downstream zingabacinga njengababoneleli bezixhobo kwinkqubo yokuvelisa i-carbon fiber. Njengoko kubonisiwe kumfanekiso:

Yonke inkqubo ukusuka kwisilika eluhlaza ukuya kwi-carbon fiber ephezulu kwishishini le-carbon fiber kufuneka idlule kwiinkqubo ezifana nee-oxidation furnaces, ii-carbonization furnaces, ii-graphitization furnaces, unyango lomphezulu, kunye nobungakanani. Ulwakhiwo lwefayibha lulawulwa yi-carbon fiber.

I-carbon fiber chain ephezulu yeshishini le-carbon fiber iphantsi kweshishini le-petrochemical, kwaye i-acrylonitrile ifunyanwa ngokucocwa kweoyile ekrwada, ukuqhekeka, i-ammonia oxidation, njl.njl.; i-polyacrylonitrile precursor fiber, i-carbon fiber ifunyanwa ngoku-pre-oxidizing kunye ne-carbonization ye-precursor fiber, kwaye izinto ezidityanisiweyo ze-carbon fiber zifunyanwa ngokucutshungulwa kwe-carbon fiber kunye ne-resin esemgangathweni ophezulu ukuhlangabezana neemfuno zesicelo.

Inkqubo yokuvelisa i-carbon fiber ibandakanya ikakhulu ukuzoba, ukudweba, ukuzinzisa, ukwenziwa kwe-carbonization, kunye nokudweba ngegrafiti. Njengoko kubonisiwe kumfanekiso:

Umzobo:Eli linyathelo lokuqala kwinkqubo yokuvelisa i-carbon fiber. Ngokuyintloko yahlula izinto ezikrwada zibe yi-fibers, nto leyo etshintsha ngokwasemzimbeni. Ngexesha lale nkqubo, ukudluliselwa kobunzima kunye nokudluliselwa kobushushu phakathi kolwelo olujikelezayo kunye nolwelo olujiyayo, kwaye ekugqibeleni yi-PAN precipitation. Iifilaments zenza isakhiwo sejeli.

Uyilo:Ifuna ubushushu obuyi-100 ukuya kwi-300 degrees ukuze isebenze kunye nefuthe lokunwebeka kweefayibha ezijolise kuzo. Kwakhona linyathelo elibalulekileyo kwi-modulus ephezulu, ukuqina okuphezulu, uxinano, kunye nokuphuculwa kweefayibha ze-PAN.

Uzinzo:Itsheyini ye-thermoplastic PAN ethe ngqo ye-macromolecular iguqulwa ibe yisakhiwo se-trapezoidal esingamelani nobushushu seplastiki ngendlela yokufudumeza kunye ne-oxidation kuma-degrees angama-400, ukuze inganyibiliki kwaye ingatshi kubushushu obuphezulu, igcine imo yefayibha, kwaye i-thermodynamics ikwimeko ezinzileyo.

Ukwenziwa kweCarbon:Kuyimfuneko ukukhupha izinto ezingezizo iikhabhoni kwi-PAN kubushushu obuyi-1,000 ukuya kwi-2,000 degrees, kwaye ekugqibeleni kuvelise iifayibha zekhabhoni ezinesakhiwo segrafiti ye-turbostratic enomxholo wekhabhoni ongaphezulu kwe-90%.

Ukwenziwa kweGraphitization: Kufuna ubushushu obuphakathi kwama-2,000 ukuya kuma-3,000 degrees ukuguqula izinto ezifakwe icarbon ezi-amorphous kunye ne-turbostratic zibe zizakhiwo zegraphite ezinemilinganiselo emithathu, eli linyathelo lobuchwepheshe eliphambili lokuphucula imodulus yeefayibha zecarbon.

Inkqubo eneenkcukacha zefayibha yekhabhoni ukusuka kwinkqubo yokuvelisa isilika eluhlaza ukuya kwimveliso egqityiweyo kukuba isilika eluhlaza yePAN iveliswa yinkqubo yangaphambili yokuvelisa isilika eluhlaza. Emva kokutsalwa kwangaphambili bubushushu obumanzi be-wire feeder, idluliselwa ngokulandelelana kwi-pre-oxidation furnace ngumatshini wokutsala. Emva kokuba ibhakiwe kumaqondo obushushu ahlukeneyo kwiqela le-pre-oxidation furnace, iifayibha ezi-oxidized zenziwa, oko kukuthi, iifayibha ezi-oxidized zangaphambili; iifayibha ezi-oxidized zangaphambili zenziwa zibe ziifayibha yekhabhoni emva kokudlula kwii-carbonization furnace eziphakathi kunye nezishushu kakhulu; iifayibha zekhabhoni emva koko ziphathwa ngomphezulu wokugqibela, ubungakanani, ukomiswa kunye nezinye iinkqubo zokufumana iimveliso zefayibha yekhabhoni. . Yonke inkqubo yokondla ngentambo okuqhubekayo kunye nolawulo oluchanekileyo, ingxaki encinci kuyo nayiphi na inkqubo iya kuchaphazela imveliso ezinzileyo kunye nomgangatho wemveliso yefayibha yekhabhoni yokugqibela. Imveliso yefayibha yekhabhoni inomsinga wenkqubo omde, amanqaku amaninzi aphambili obuchwephesha, kunye nemiqobo ephezulu yemveliso. Kukudityaniswa kwezifundo ezininzi kunye nobuchwepheshe.

Oku kungasentla kukwenziwa kwe-carbon fiber, makhe sijonge indlela esetyenziswa ngayo ilaphu le-carbon fiber!

Ukucutshungulwa kweemveliso zelaphu le-carbon fiber

1. Ukusika

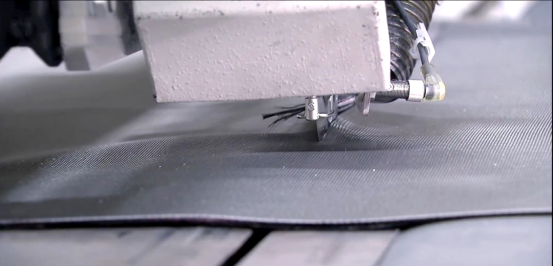

I-prepreg ikhutshwa kwindawo yokugcina ebandayo kumaqondo obushushu angaphantsi kwe-18 degrees. Emva kokuvuka, inyathelo lokuqala kukusika ngokuchanekileyo izinto ngokwedayagram yezinto ezikumatshini wokusika ozenzekelayo.

2. Ukugangatha indle

Inyathelo lesibini kukubeka isixhobo sokubeka, uze ubeke iileya ezahlukeneyo ngokweemfuno zoyilo. Zonke iinkqubo zenziwa phantsi kwe-laser positioning.

3. Ukwenziwa

Ngerobhothi yokuphatha ezenzekelayo, i-preform ithunyelwa kumatshini wokubumba ukuze i-compression molding.

4. Ukusika

Emva kokuyilwa, i-workpiece ithunyelwa kwindawo yokusebenza yerobhothi yokusika inyathelo lesine lokusika nokususa iimbumbulu ukuqinisekisa ukuchaneka kobukhulu be-workpiece. Le nkqubo ingasetyenziswa nakwi-CNC.

5. Ukucoca

Inyathelo lesihlanu kukucoca umkhenkce owomileyo kwindawo yokucoca ukuze kususwe into ekhupha inkunkuma, nto leyo elungele inkqubo yokugquma iglu elandelayo.

6. Iglu

Inyathelo lesithandathu kukufaka iglu yolwakhiwo kwisikhululo serobhothi yokuncamathelisa. Indawo yokuncamathelisa, isantya seglu, kunye nemveliso yeglu zonke zilungiswe ngokuchanekileyo. Inxalenye yoqhagamshelwano neendawo zesinyithi iravetiwe, eyenziwa kwisikhululo sokuncamathelisa.

7. Ukuhlolwa kwendibano

Emva kokuba iglu isetyenzisiwe, iiphaneli zangaphakathi nezangaphandle ziyahlanganiswa. Emva kokuba iglu ilungisiwe, kukhangelwa ukukhanya okuluhlaza okwesibhakabhaka ukuqinisekisa ukuchaneka kobukhulu bemingxuma yezitshixo, amanqaku, imigca kunye nomphezulu.

I-carbon fiber inzima ukuyicubungula

I-carbon fiber inamandla okutsalwa aqinileyo ezinto zekhabhoni kunye nokuthamba kwefayibha. I-carbon fiber yinto entsha eneempawu ezintle zoomatshini. Umzekelo, i-carbon fiber kunye nentsimbi yethu eqhelekileyo, amandla e-carbon fiber amalunga ne-400 ukuya kwi-800 MPa, ngelixa amandla entsimbi eqhelekileyo angama-200 ukuya kwi-500 MPa. Xa ujonga ukuqina, i-carbon fiber kunye nentsimbi ziyafana, kwaye akukho mahluko ucacileyo.

I-carbon fiber inamandla aphezulu kwaye inobunzima obulula, ngoko ke i-carbon fiber inokubizwa ngokuba yikumkani yezinto ezintsha. Ngenxa yale nzuzo, ngexesha lokucubungula i-carbon fiber reinforced composites (CFRP), i-matrix kunye ne-fibers zinentsebenziswano yangaphakathi enzima, okwenza iipropati zazo zomzimba zahluke kwezo zesinyithi. Ubuninzi be-CFRP buncinci kakhulu kunobo besinyithi, ngelixa amandla makhulu kunezinye iisinyithi. Ngenxa yokungafani kwe-CFRP, i-fiber pull-out okanye i-matrix fiber detachment idla ngokuvela ngexesha lokucubungula; i-CFRP inokumelana nobushushu okuphezulu kwaye iyamelana nokuguguleka, nto leyo eyenza kube nzima kakhulu kwizixhobo ngexesha lokucubungula, ngoko ke inani elikhulu lobushushu obunqunyiweyo lwenziwa kwinkqubo yemveliso, nto leyo ebaluleke ngakumbi ekugugulekeni kwezixhobo.

Kwangaxeshanye, njengoko kuqhubeka ukwandiswa kweendawo zayo zokusetyenziswa, iimfuno ziya zisiba buthathaka ngakumbi nangakumbi, kwaye iimfuno zokusetyenziswa kwezixhobo kunye neemfuno zomgangatho we-CFRP ziya zisiba nzima ngakumbi, nto leyo ebangela ukuba iindleko zokucubungula zinyuke.

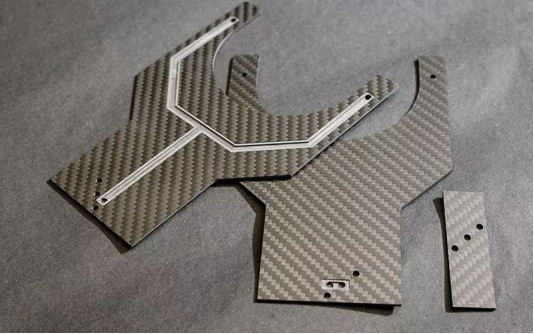

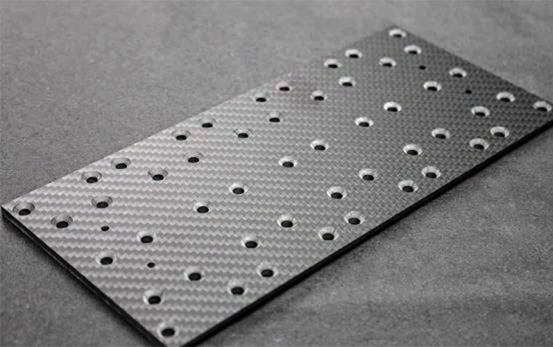

Ukucutshungulwa kwebhodi yefayibha yekhabhoni

Emva kokuba ibhodi yefayibha yekhabhoni ilungisiwe kwaye yenziwe, ukucubungula emva kokwenza okufana nokusika nokubhola kuyadingeka kwiimfuno ezichanekileyo okanye iimfuno zokuhlanganisa. Phantsi kweemeko ezifanayo ezifana neeparameter zenkqubo yokusika kunye nobunzulu bokusika, ukukhetha izixhobo kunye nokubhola kwezinto ezahlukeneyo, ubungakanani kunye neemilo kuya kuba nemiphumo eyahlukileyo kakhulu. Kwangaxeshanye, izinto ezifana namandla, ulwalathiso, ixesha, kunye nobushushu bezixhobo kunye nokubhola ziya kuchaphazela iziphumo zokucubungula.

Kwinkqubo emva kokucubungula, zama ukukhetha isixhobo esibukhali esinedayimani kunye ne-carbide drill bit eqinileyo. Ukumelana nokuguguleka kwesixhobo kunye ne-drill bit ngokwayo kumisela umgangatho wokucubungula kunye nobomi benkonzo yesixhobo. Ukuba isixhobo kunye ne-drill bit azibukhali ngokwaneleyo okanye azisetyenziswanga kakuhle, aziyi kukhawulezisa kuphela ukuguguleka, zonyuse iindleko zokucubungula imveliso, kodwa zikwabangela umonakalo kwipleyiti, zichaphazela imo kunye nobukhulu bepleyiti kunye nokuzinza kobukhulu bemingxuma kunye nemingxunya kwipleyiti. Zibangela ukukrazulwa kwezinto, okanye zide zidilike iibhloko, okubangela ukukrazulwa kwebhodi yonke.

Xa kugrunjwaamaphepha efayibha yekhabhoni, okukhona isantya sikhawuleza, kokukhona isiphumo siba ngcono. Ekukhetheni ii-drill bits, uyilo olukhethekileyo lwe-drill tip ye-PCD8 face edge drill bit lufanelekile ngakumbi kwii-carbon fiber sheets, ezinokungena ngcono kwii-carbon fiber sheets kwaye zinciphise umngcipheko we-delamination.

Xa usika amaphepha e-carbon fiber aqinileyo, kucetyiswa ukuba usebenzise i-compression milling cutter enemiphetho emibini enoyilo lomphetho we-helical wasekhohlo nasekunene. Olu hlangothi lokusika olubukhali luneencopho ze-helical eziphezulu nezisezantsi zokulinganisela amandla e-axial esixhobo phezulu nasezantsi ngexesha lokusika. , ukuqinisekisa ukuba amandla okusika aphumayo ajoliswe kwicala langaphakathi lesixhobo, ukuze kufunyanwe iimeko zokusika ezizinzileyo kwaye kuthintelwe ukwenzeka kokuqhekeka kwezinto. Uyilo lwemiphetho ephezulu nesezantsi efana nedayimani ye-"Pineapple Edge" router lunokusika ngempumelelo amaphepha e-carbon fiber. I-deep chip flute yayo inokususa ubushushu obuninzi ngokukhupha ii-chips ngexesha lenkqubo yokusika, ukuze kuthintelwe ukonakala kweempawu zephepha le-carbon fiber.

01 Ifayibha ende eqhubekayo

Iimpawu zemveliso:Eyona mveliso ixhaphakileyo yabavelisi be-carbon fiber, le bundle yenziwe ngamawaka ee-monofilaments, ezahlulwe zibe ziintlobo ezintathu ngokwendlela yokujika: i-NT (Never Twisted, untwisted), i-UT (Untwisted, untwisted), i-TT okanye i-ST (Twisted, twisted), apho i-NT yeyona fiber yekhabhoni isetyenziswa kakhulu.

Isicelo esiphambili:Isetyenziswa kakhulu kwizinto ezidityanisiweyo ezifana nezinto ezidityanisiweyo zeCFRP, CFRTP okanye C/C, kwaye amacandelo okusetyenziswa aquka izixhobo zeenqwelo-moya/zeenqwelo-moya, iimpahla zemidlalo kunye nezixhobo zemizi-mveliso.

02 Intambo yeStaple Fiber

Iimpawu zemveliso:Intambo yefayibha emfutshane yemisonto emifutshane, imisonto ephothiweyo kwimisonto yekhabhoni emfutshane, njengemisonto yekhabhoni esekwe kwipitch, idla ngokuba yimveliso ngendlela yemisonto emifutshane.

Iindlela eziphambili zokusetyenziswa:izixhobo zokuthintela ukufudumeza, izixhobo zokulwa nokungqubana, iindawo ezidityanisiweyo ze-C/C, njl.

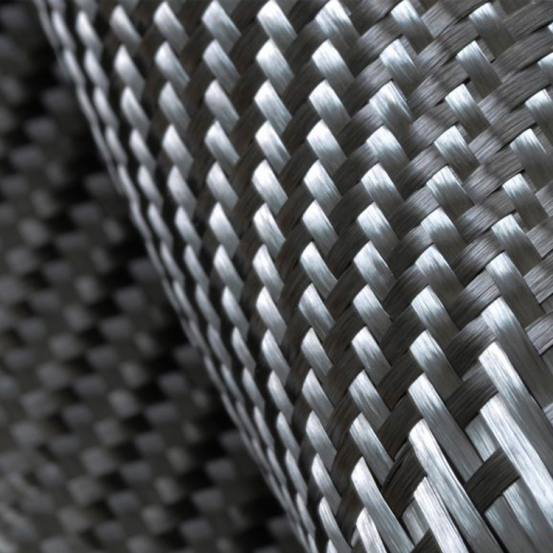

03 Ilaphu leCarbon Fiber

Iimpawu zemveliso:Yenziwe ngefayibha yekhabhoni eqhubekayo okanye intambo ephothiweyo yefayibha yekhabhoni. Ngokwendlela yokuluka, amalaphu efayibha yekhabhoni anokwahlulwa abe ngamalaphu alukiweyo, amalaphu alukiweyo kunye namalaphu angalukiweyo. Okwangoku, amalaphu efayibha yekhabhoni adla ngokuba ngamalaphu alukiweyo.

Isicelo esiphambili:Ifana ne-carbon fiber eqhubekayo, esetyenziswa kakhulu kwizinto ezidityanisiweyo ezifana ne-CFRP, i-CFRTP okanye izinto ezidityanisiweyo ze-C/C, kwaye amacandelo okusetyenziswa aquka izixhobo zeenqwelo-moya/zeenqwelo-moya, iimpahla zemidlalo kunye nezixhobo zemizi-mveliso.

Ibhanti Elukiweyo Ye-Carbon Fiber ye-04

Iimpawu zemveliso:Yeyohlobo oluthile lwelaphu le-carbon fiber, elikwalukwa nge-carbon fiber eqhubekayo okanye i-carbon fiber spun warn.

Ukusetyenziswa okuphambili:Isetyenziswa kakhulu kwizinto zokuqinisa ezisekelwe kwi-resin, ingakumbi ekuveliseni nasekucubunguleni iimveliso zetyhubhu.

05 Ifayibha yekhabhoni enqunqiweyo

Iimpawu zemveliso:Ngokungafaniyo nengcamango yentambo ephothiweyo yefayibha yekhabhoni, idla ngokulungiswa ngefayibha yekhabhoni eqhubekayo ngokusebenzisa ukucutshungulwa okunqunqiweyo, kwaye ubude befayibha obunqunqiweyo bunganqunyulwa ngokweemfuno zabathengi.

Iindlela eziphambili zokusetyenziswa:Ngokwesiqhelo isetyenziswa njengomxube weplastiki, iiresini, isamente, njl.njl., ngokuxuba kwi-matrix, iipropati zoomatshini, ukumelana nokuguguleka, ukuhanjiswa kombane kunye nokumelana nobushushu kunokuphuculwa; kwiminyaka yakutshanje, iifayibha zokuqinisa kwi-3D printing fiber composites ikakhulu ziifayibha zekhabhoni ezinqunqiweyo.

06 Ukusila ifayibha yekhabhoni

Iimpawu zemveliso:Ekubeni i-carbon fiber iyinto ebuthathaka, ingalungiswa ibe yi-carbon fiber emva kokugaywa, oko kukuthi, ukugaywa kwe-carbon fiber.

Isicelo esiphambili:ifana nefayibha yekhabhoni eqoshiweyo, kodwa ayisetyenziswa rhoqo ekuqiniseni isamente; idla ngokusetyenziswa njengekhompawundi yeplastiki, iresin, irabha, njl. ukuphucula iipropati zoomatshini, ukumelana nokuguguleka, ukuhanjiswa kombane kunye nokumelana nobushushu be-matrix.

07 I-Carbon fiber mat

Iimpawu zemveliso:Uhlobo oluphambili yifelt okanye i-mat. Okokuqala, iifayibha ezimfutshane zifakwa kwi-mechanical carding kunye nezinye iindlela, zize zilungiswe ngokubhoboza ngeenaliti; okwaziwa ngokuba yi-carbon fiber non-woven fabric, iyinxalenye yohlobo lwelaphu elilukiweyo le-carbon fiber.Iindlela eziphambili zokusetyenziswa:izixhobo zokukhusela ubushushu, izixhobo zokukhusela ubushushu ezibunjiweyo, iileya zokukhusela ezimelana nobushushu kunye nezixhobo zokukhusela ubushushu ezimelana nokugqwala, njl.

08 Iphepha le-carbon fiber

Iimpawu zemveliso:Ilungiswa ngefayibha yekhabhoni ngenkqubo yokwenza iphepha elomileyo okanye elimanzi.

Iindlela eziphambili zokusetyenziswa:iipleyiti ezichasene nokuma, ii-electrode, iikhowuni zesithethi kunye neepleyiti zokufudumeza; usetyenziso olushushu kwiminyaka yakutshanje zizixhobo ze-cathode zebhetri yesithuthi samandla amatsha, njl.

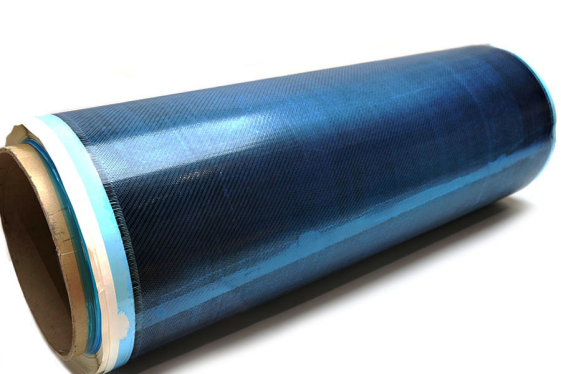

09 Ukulungiselela ifayibha yekhabhoni

Iimpawu zemveliso:izinto eziphakathi eziqinisiweyo ezenziwe nge-carbon fiber efakwe kwi-thermosetting resin, ezineempawu ezintle kakhulu zoomatshini kwaye zisetyenziswa kakhulu; ububanzi be-carbon fiber prepreg buxhomekeke kubungakanani bezixhobo zokucubungula, kwaye iinkcukacha eziqhelekileyo ziquka izinto zokulungiselela ububanzi be-300mm, 600mm, kunye ne-1000mm.

Isicelo esiphambili:izixhobo zeenqwelo-moya/zeenqwelo-moya, iimpahla zemidlalo kunye nezixhobo zoshishino, njl.

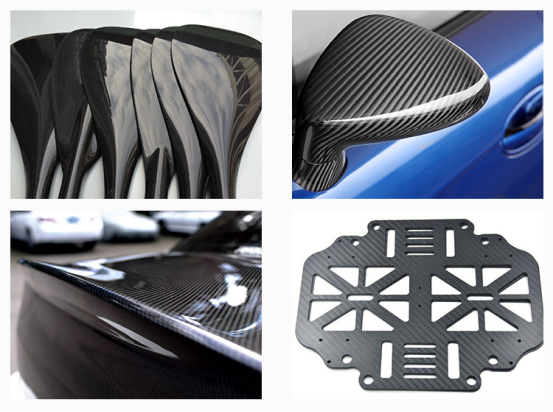

Izinto ezidityanisiweyo zefayibha yekhabhoni ze-010

Iimpawu zemveliso:Izinto zokubumba ezenziwe nge-thermoplastic okanye i-thermosetting resin exutywe ne-carbon fiber, umxube wongezwa kunye nezongezo ezahlukeneyo kunye neefayibha ezinqunqiweyo, uze emva koko ungene kwinkqubo yokudibanisa.

Isicelo esiphambili:Ixhomekeke kumbane ogqwesileyo wezixhobo, ukuqina okuphezulu kunye neenzuzo ezilula, isetyenziswa kakhulu kwiibhokisi zezixhobo kunye nezinye iimveliso.

Sikwavelisai-fiberglass ejikelezayo ngqo,iimathi zefiberglass, i-fiberglass mesh, kwayeukuzulazula okulukiweyo kwefayibha.

Qhagamshelana nathi :

Inombolo yefowuni:+8615823184699

Inombolo yefowuni: +8602367853804

Email:marketing@frp-cqdj.com

Ixesha lokuthumela: Juni-01-2022