Kwimeko eguquka ngokukhawuleza kwishishini leemoto kwihlabathi liphela, umdyarho oyaukuhambahamba kombane (i-EV)kwaye ukusetyenziswa kakuhle kwepetroli kuye kwatshintsha ingqwalasela ukusuka ekusebenzeni kwenjini ukuya kwisayensi yezinto eziphathekayo. Isiseko sale nguqu kulapho kukho ingcamango yokubaUbunzima beeMotoNangona ii-alloys eziphambili kunye ne-carbon fiber zihlala zisiba iindaba eziphambili,ukuzulazula ngefiberglassiye yavela njengeqhawe elingadunyiswanga, ibonelela ngesisombululo esingabizi kakhulu nesisebenza kakuhle sokwenza izixhobo zezithuthi zesizukulwana esilandelayo.

Utshintsho Lweqhinga: Kutheni I-Fiberglass Ihambahamba?

Icandelo leemoto okwangoku lijongene nemingeni emibini: ukunciphisa ukukhutshwa kwekhabhoni kwiimoto ze-injini yokutsha yangaphakathi (ICE) kunye nokwandisa uluhlu lwebhetri kwiimoto zombane (ii-EV). Ukunciphisa ubunzima yeyona nto isebenzayo yokutsala zombini. Idatha yeshishini ibonisa ukubaUkunciphisa ubunzima besithuthi nge-10%kunokukhokelela kwiUphuculo lwe-6–8% kwindlela esetyenziswa ngayo amafuthaokanye ukunyuka okukhulu kwi-EV mileage.

Ukuzulazula kwe-fiberglass, ngakumbiukuhambahamba ngqokwayeukuhambahamba okudibeneyo, inikezela ngeseti ekhethekileyo yeempawu ezenza ukuba ibaluleke kakhulu kubaboneleli banamhlanje beTier-1:

Umlinganiselo ongaqhelekanga woBunzima boMzimba:Nangona zikhaphukhaphu kakhulu kunentsimbi okanye i-aluminium, izinto eziqiniswe ngefayibha yeglasi zinokumelana noxinzelelo olukhulu loomatshini.

Ukumelana nokugqwala:Ngokungafaniyo neentsimbi, i-fiberglass ayigqwali, nto leyo eyandisa ubomi be-chassis kunye nezinto ezingaphantsi komzimba.

Ukuguquguquka koyilo:Ukusetyenziswa kokujikeleza kwiinkqubo ezifanai-pultrusionkwayeI-SMC (iCompound yokubumba amaphepha)ivumela iijometri ezintsonkothileyo ezingenakwenzeka ngokunyathela isinyithi ngokwesiko.

Izicelo eziphambili kwiZithuthi zeSizukulwana Esilandelayo

Ukuguquguquka kwezintoukuzulazula ngefiberglassibonakaliswa ngcono ngezicelo zayo ezahlukeneyo kuyilo lwezithuthi zanamhlanje.

1. Iibhetri ze-EV ezivalekileyo

Njengeyona nto inzima kwisithuthi sombane, ibhetri ifuna indawo ekhaphukhaphu engapheleli nje ekubeni lula kodwa ekwaziyo ukuthintela umlilo kwaye ekhuselweyo ngombane.Ukuhambahamba nge-fiberglass, xa idityaniswe nee-resin ze-thermoset ezikhethekileyo, idala indawo ebiyelweyo ekhusela iiseli zebhetri ngelixa inegalelo ekuqineni kwesakhiwo semoto iyonke.

2. Iinkqubo zeLeaf Springs kunye neSuspension

Imithombo yamagqabi entsimbi yendabuko inzima kwaye idla ngokudinwa. Ngokusebenzisa i-fiberglass ene-modulus ephezulu ejikelezayo kwinkqubo ye-pultrusion, abavelisi banokuvelisa imithombo yamagqabi edibeneyo efikelela kwiI-75% ekhaphukhaphukuneentsimbi ezisetyenziswa kuzo, zibonelela ngeempawu zokufunxa amanzi ezingcono kunye nokuhamba kakuhle.

3. Izikhuselo ezingaphantsi komzimba kunye neeBrackets zesakhiwo

Inxalenye engaphantsi kwesithuthi ichaphazeleka ziinkunkuma zendlela ezirhabaxa kunye nokufuma. Ii-thermoplastics eziqiniswe nge-fiberglass (CFRTP) ezisebenzisa i-long fiber roving zibonelela ngokumelana okuphezulu, zikhusela "amalungu abalulekileyo" esithuthi ngaphandle kokongeza ubuninzi be-heavy metal shield shield.

Indima yeTekhnoloji yokuHamba ePhambili: i-E-Glass vs. iGlasi yeModulus ephezulu

Ukuze kuhlangatyezwane neemfuno ezingqongqo zoshishino lweemoto, ayizizo zonke ii-fiberglass roving ezidalwe zilingana. Ukukhethwa kwefayibha kumisela ukusebenza kokugqibela kwenxalenye.

Ukuhambahamba ngeglasi ye-E:Umgangatho weshishini, obonelela ngobushushu bombane obugqwesileyo kunye neempawu zoomatshini ngexabiso eliphantsi. Ihlala iyinto ethandwayo kwiiphaneli zangaphakathi nezangaphandle eziqhelekileyo.

Ukuhambahamba ngeModulus ePhakamileyo (HM):Kwizinto ezifuna ukuqina kakhulu, njengeentsika zophahla okanye izakhelo zeminyango, i-HM roving ibonelela ngemodulus evala umsantsa phakathi kwefayibha yeglasi yendabuko kunye nefayibha yekhabhoni ebiza kakhulu.

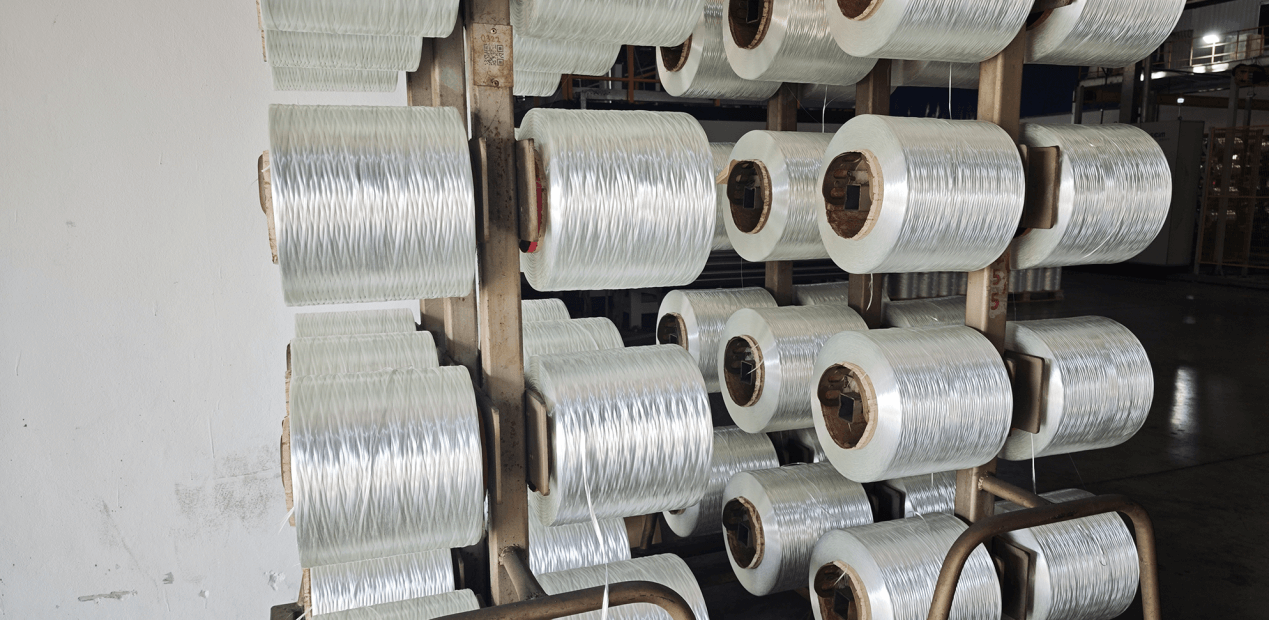

At [I-CQDJ], sigxile ekuveliseni i-fiberglass roving nge-advancediinkqubo zokulinganisa—i-chemical coating esetyenziswa kwiifayibha. Ubungakanani bethu obukhethekileyo buqinisekisa unxibelelwano olugqibeleleyo phakathi kwefayibha kunye ne-resin matrix (nokuba yi-Epoxy, iPolyester, okanye iPolypropylene), nto leyo ibalulekileyo ekuthinteleni ukuqhekeka kunye nokuqinisekisa ukuqina kwexesha elide kwiindawo zeemoto ezinokungcangcazela kakhulu.

Ukuzinza: Uqoqosho olujikelezayo lweFiber yeGlasi

Ingcamango ephosakeleyo eqhelekileyo kukuba izinto ezidityanisiweyo azinabungozi kwindalo. Nangona kunjalo, intshukumo iya phambiliukuzulazula nge-thermoplastic (TP)iyatshintsha ibali. Ngokungafaniyo neethermosets, ukuzulazula okufakwe kwi-thermoplastic kunokunyibilikiswa kwaye kutshintshwe, oku kuvula ucango lokurisayikilisha iindawo zeemoto ekupheleni komjikelo wobomi besithuthi. Ngaphezu koko, amandla afunekayo ukuvelisa ukuzulazula kwefiberglass aphantsi kakhulu kunalawo e-aluminium okanye i-carbon fiber, nto leyo enciphisa "i-carbon embedded" yesithuthi ukususela ngomhla wokuqala.

Iingcaciso ze-SEO zabaphathi bokuthenga

Xa ufuna ulwaziukuzulazula ngefiberglassKwizicelo zeemoto, akwanelanga ukujonga "ixabiso ngetoni." Amaqela okuthenga ngoku agxile koku kulandelayo:

1.Amandla okuThamba (MPa):Ukuqinisekisa ukuba ifayibha iyakwazi ukumelana nomthwalo.

2.Ukuhambelana:Ngaba ukuzulazula kusebenza neenkqubo ezithile ze-resin (PA6, PP, okanye Epoxy)?

3.Ukungaguquguquki:Ngaba ukuhambahamba kunika uxinzelelo olufanayo kunye nokungabi namandla kangako, okuthintela ixesha lokungasebenzi kwimigca yemveliso ezenzekelayo?

Isiphelo

Ikamva leshishini leemoto lilula, liqinile, kwaye lizinzile ngakumbi. Njengoko sisiya nzulu kweli shumi leminyaka, ukuhlanganiswa kweukuzulazula ngefiberglassukuba zibe zizixhobo zezithuthi ezisemgangathweni nezisebenzayo kuya kukhawulezisa kuphela. Ngokutshintsha iintsimbi ezinzima ngee-composites ezisebenzayo kakhulu, abavelisi abakhi nje iimoto, kodwa baceba ikamva lokuhambahamba.

Indlela Esinokunceda Ngayo

Njengomvelisi okhokelayo we-fiberglass roving esebenza kakuhle,[I-CQDJ]Ibonelela ngezisombululo ezenzelwe wena kwikhonkco lokubonelela ngeemoto. Iimveliso zethu zenzelwe ukuphucula iinkqubo ze-pultrusion, SMC, kunye ne-LFT (Long Fiber Thermoplastic).

Ixesha leposi: Disemba-19-2025