Uphando lwePricelist

Ukuba unemibuzo malunga neemveliso zethu okanye uluhlu lwamaxabiso, nceda usishiyele i-imeyile yakho kwaye siya kuqhagamshelana nathi kwiiyure ezingama-24.

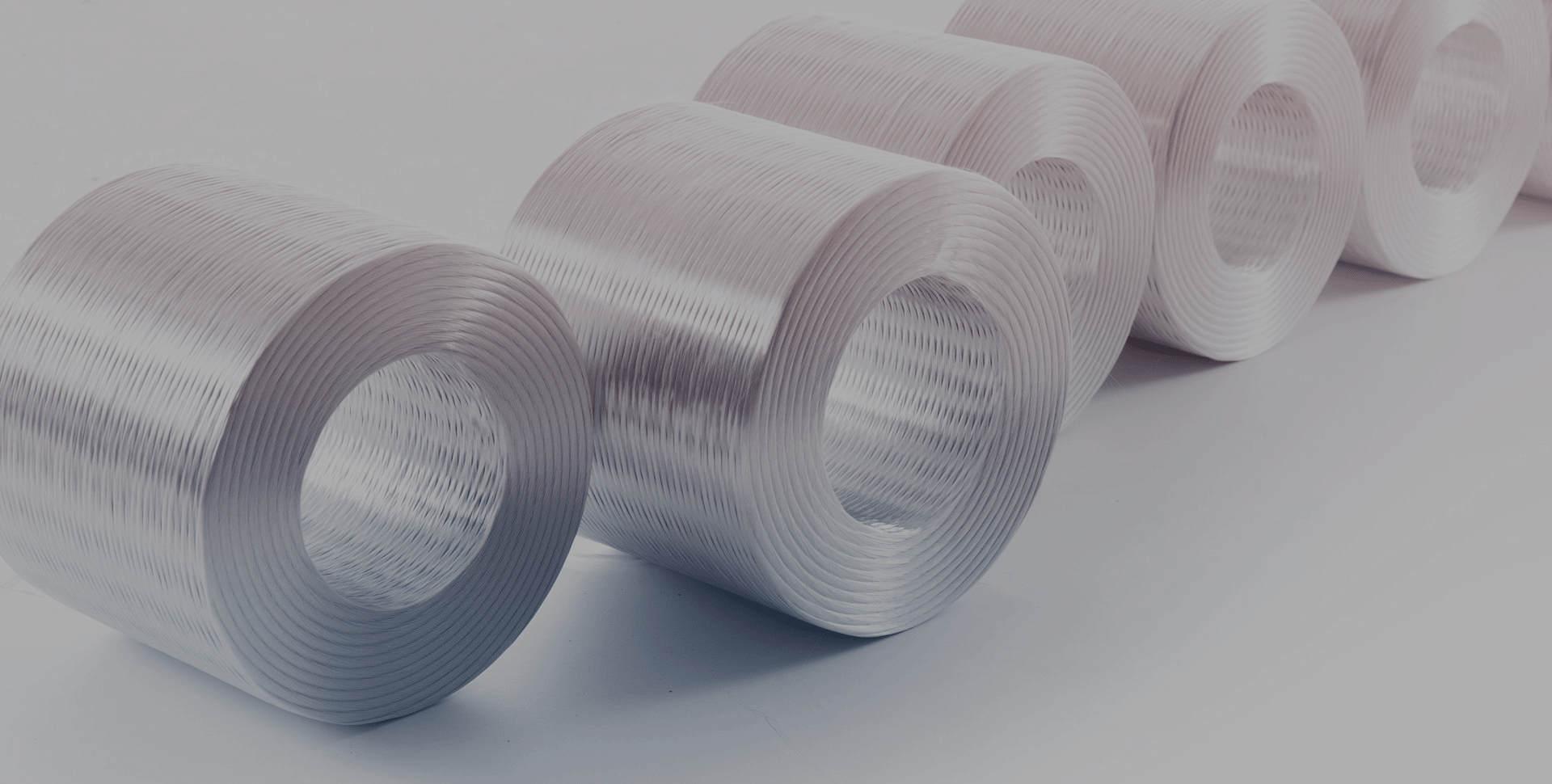

Iglasi yefayibhaukuhambahamba ngqoIimbonakalo:

• Ukusebenza kakuhle kwenkqubo kunye nokungabi namandla aneleyo.

• Ukuhambelana neenkqubo ezininzi ze-resin.

• Ukumanzisa ngokupheleleyo nangokukhawuleza.

• Iimpawu ezilungileyo zoomatshini.

• Ukumelana kakuhle nokugqwala kwe-asidi.

• Ukumelana nokwaluphala okugqwesileyo.

Sineentlobo ezininzi zeukuzulazula kwefiberglass:ukuzulazula kwephaneli,ukutshiza phezulu uhambahamba,Ukuhambahamba kwe-SMC,ukuhambahamba ngqo,ukuzulazula ngeglasi ckunyeukuzulazula kwefiberglass yokugawula.

| Uxinano oluLula (%) | Umxholo wobumanzi (%) | Ubungakanani bomxholo (%) | Amandla okuphuka (N/Tex ) |

| I-ISO 1889 | I-ISO 3344 | I-ISO 1887 | I-ISO 3375 |

| ± 5 | ≤ 0.10 | 0.50 ± 0.15 | ≥0.40(≤17um)≥0.35(17~24um)≥0.30(≥24um) |

Uluhlu olubanzi lwezicelo - zilungele iimeko ezahlukeneyo, iitanki ze-FRP, iinqaba zokupholisa ze-FRP, izixhobo zemodeli ze-FRP, iishedi zeethayile zokukhanyisa, iinqanawa, izixhobo zeemoto, iiprojekthi zokukhusela okusingqongileyo, izixhobo zokwakha ezintsha zokufulela, iibhafu, njl.njl.

Zethuiimathi zefiberglassziindidi ezininzi:iimathi zomphezulu wefiberglass,iimathi zefiberglass ezinqunqiweyokunyeiimathi zefiberglass eziqhubekayo. I-strand mat eqoshiweyoyahlulwe yaba yi-emulsion kwayeiimathi zefayibha zeglasi yomgubo.

•Iimveliso zeFiberglass ezijikelezayo ngqo kufuneka igcinwe kwindawo eyomileyo, epholileyo, nengafumiyo.

•Iglasi yefayibhaukuhambahamba ngqoiimvelisokufuneka zigcinwe kwiphakheji yazo yokuqala ngaphambi kokuba zisetyenziswe. Ubushushu begumbi kunye nokufuma kufuneka kugcinwe kwi -10 °C ~ 35 °C kunye ne ≤ 80%, ngokulandelelana.

• Ukuqinisekisa ukhuseleko kunye nokuphepha ukonakalisa imveliso, ukuphakama kwenqwaba yeepalethi akufuneki kudlule kwiileya ezintathu.

• Xa iipalethi zibekwe zibe ziileya ezimbini okanye ezintathu, kufuneka kuqwalaselwe ngokukodwa ukuhambisa itreyi ephezulu ngokuchanekileyo nangokutyibilikayo.

| Uhlobo lweglasi | E6 | ||||||

| Uhlobo lobukhulu | ISilane | ||||||

| Ikhowudi yobukhulu | 386H | ||||||

| Uxinano oluLula (i-tex) | 300 | 600 | 1200 | 2200 | 2400 | 4800 | 9600 |

| Ububanzi bentambo (μm) | 13 | 17 | 17 | 23 | 17/24 | 24 | 31 |

| Iipropati zoomatshini | Iyunithi | Ixabiso | I-resin | Indlela |

| Tensile strength | I-MPa | 2765 | UP | I-ASTM D2343 |

| Imodulus yokuThatha | I-MPa | 81759 | UP | I-ASTM D2343 |

| Amandla okucheba | I-MPa | 2682 | EP | I-ASTM D2343 |

| Imodulus yokuThatha | I-MPa | 81473 | EP | I-ASTM D2343 |

| Amandla okucheba | I-MPa | 70 | EP | I-ASTM D2344 |

| Ukugcinwa kwamandla okucheba (ukubila iiyure ezingama-72) | % | 94 | EP | / |

Imemo: Idatha engentla ngamaxabiso okwenyani ovavanyo lwe-E6DR24-2400-386H kwaye yenzelwe ukubhekisela kuphela

| Ukuphakama kwephakheji mm (ngaphakathi) | 260 (10.2) | 260 (10.2) |

| Iphakheji ngaphakathi kobubanzi mm (ngaphakathi) | 160 (6.3) | 160 (6.3) |

| Iphakheji ngaphandle kobubanzi mm (ngaphakathi) | 275 (10.6) | 310 (12.2) |

| Ubunzima bephakheji kg (lb) | 15.6 (34.4) | 22 (48.5) |

| Inani leeleya | 3 | 4 | 3 | 4 |

| Inani lee-doffs ngomaleko ngamnye | 16 | 12 | ||

| Inani leedoffs ngepallet nganye | 48 | 64 | 36 | 48 |

| Ubunzima obupheleleyo ngepallet nganye nge kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Iglasi yefayibhaukuhambahamba ngqo Ubude bepalethi mm (ngaphakathi) | 1120 (44.1) | 1270 (50.0) | ||

| Iglasi yefayibhaukuhambahamba ngqo Ububanzi bepalethi mm (ngaphakathi) | 1120 (44.1) | 960 (37.8) | ||

| Iglasi yefayibhaukuhambahamba ngqo Ukuphakama kwepalethi mm (ngaphakathi) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Ngaphandle kokuba kuchazwe ngenye indlela,Iglasi yefayibhaukuhambahamba ngqokufuneka igcinwe kwindawo eyomileyo, epholileyo nengafumiyo.

• Iimveliso zefiberglass mazihlale kwiphakheji yazo yokuqala de kube ngaphambi kokuba zisetyenziswe. Ubushushu begumbi kunye nokufuma kufuneka kugcinwe rhoqo kwi -10℃ ~ 35℃ kunye ne ≤80% ngokulandelelana.

• Ukuqinisekisa ukhuseleko kunye nokuphepha ukonakala kwemveliso, iipalethi akufuneki zibekwe ngaphezulu kweengqimba ezintathu ukuphakama.

• Xa iipallet zibekwe ngokweeleya ezimbini okanye ezintathu, kufuneka kuthathwe ingqalelo ekhethekileyo ukuze ipallet ephezulu ishukunyiswe ngokuchanekileyo nangokutyibilikayo.

Ukuba unemibuzo malunga neemveliso zethu okanye uluhlu lwamaxabiso, nceda usishiyele i-imeyile yakho kwaye siya kuqhagamshelana nathi kwiiyure ezingama-24.