Uphando lwePricelist

Ukuba unemibuzo malunga neemveliso zethu okanye uluhlu lwamaxabiso, nceda usishiyele i-imeyile yakho kwaye siya kuqhagamshelana nathi kwiiyure ezingama-24.

• Iipropati ezibalaseleyo zokucubungula, akukho fuzz ininzi.

• Ukuhambelana kwe-multi-resin.

• Ukumanzisa ngokukhawuleza nangokupheleleyo.

• Iimpawu ezilungileyo zoomatshini zezixhobo ezigqityiweyo.

• Ukumelana kakuhle nokugqwala kweekhemikhali.

Ukukhangela umthombo othembekileyo weUkuzulazula ngqo kweFiberglass? Sukujonga phambili! YethuUkuzulazula ngqo kweFiberglassyenziwe kusetyenziswa iteknoloji ephucukileyo kunye nezixhobo ezikumgangatho ophezulu, ukuqinisekisa ukusebenza kakuhle kunye nokuqina. Yenzelwe uluhlu olubanzi lwezicelo, yethuUkuzulazula ngqo kweFiberglassInika iipropati ezibalaseleyo zokumanzisa, nto leyo evumela ukufunxwa kweresin efanelekileyo ukuze komelele kwaye kuqine. Nokuba uyayidinga kwimveliso yee-composites, i-pultrusion, i-filament winding, okanye ezinye iindlela zokusebenza, yethuUkuzulazula ngqo kweFiberglasslukhetho olufanelekileyo. Qhagamshelana nathi namhlanje ukuze ufunde okungakumbi malunga ne-intanethi yethuUkuzulazula ngqo kweFiberglasskwaye ufumanise indlela enokuyiphakamisa ngayo inkqubo yakho yemveliso iye kwinqanaba elitsha.

•Ukuzulazula ngokuthe ngqoifanelekile ukusetyenziswa kwimibhobho, kwimithambo yoxinzelelo, kwiigrating, nakwiiprofayili, kwayeiirovings ezilukiweyo eziguqulwe kuyo zisetyenziswa kwiinqanawa nakwiitanki zokugcina iikhemikhali.

Sineentlobo ezininzi zeukuzulazula kwefiberglass:ukuzulazula kwephaneli,ukutshiza phezulu uhambahamba,Ukuhambahamba kwe-SMC,ukuhambahamba ngqo,ukuzulazula ngeglasi ckunyeukuzulazula kwefiberglassyokugawula.

| Uhlobo lweglasi | I-E6-fiberglass ejikelezayo ngqo | ||||||||

| Uhlobo lobukhulu | ISilane | ||||||||

| Ikhowudi yobukhulu | 386T | ||||||||

| Uxinano oluLula(iteksi) | 300 | 200 400 | 200 600 | 735 900 | 1100 1200 | 2000 | 2200 | 2400 4800 | 9600 |

| Ububanzi bentambo (μm) | 13 | 16 | 17 | 17 | 17 | 21 | 22 | 24 | 31 |

| Uxinano oluLula (%) | Umxholo wobumanzi (%) | Ubungakanani bomxholo (%) | Amandla okuphuka (N/Tex ) |

| I-ISO 1889 | I-ISO3344 | I-ISO1887 | I-ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40(≤2400tex)≥0.35(2401~4800tex)≥0.30(>4800tex) |

| Iipropati zoomatshini | Iyunithi | Ixabiso | I-resin | Indlela |

| Tensile strength | I-MPa | 2660 | UP | I-ASTM D2343 |

| Imodulus yokuThatha | I-MPa | 80218 | UP | I-ASTM D2343 |

| Amandla okucheba | I-MPa | 2580 | EP | I-ASTM D2343 |

| Imodulus yokuThatha | I-MPa | 80124 | EP | I-ASTM D2343 |

| Amandla okucheba | I-MPa | 68 | EP | I-ASTM D2344 |

| Ukugcinwa kwamandla okucheba (ukubila iiyure ezingama-72) | % | 94 | EP | / |

Imemo:Idatha engentla ngamaxabiso okwenyani ovavanyo lwe-E6DR24-2400-386H kwaye yenzelwe ukubhekisela kuphela

| Ukuphakama kwephakheji mm (ngaphakathi) | 255(10) | 255(10) |

| Iphakheji ngaphakathi kobubanzi mm (ngaphakathi) | 160 (6.3) | 160 (6.3) |

| Iphakheji ngaphandle kobubanzi mm (ngaphakathi) | 280(1)1) | 310 (12.2) |

| Ubunzima bephakheji kg (lb) | 15.6 (34.4) | 22 (48.5) |

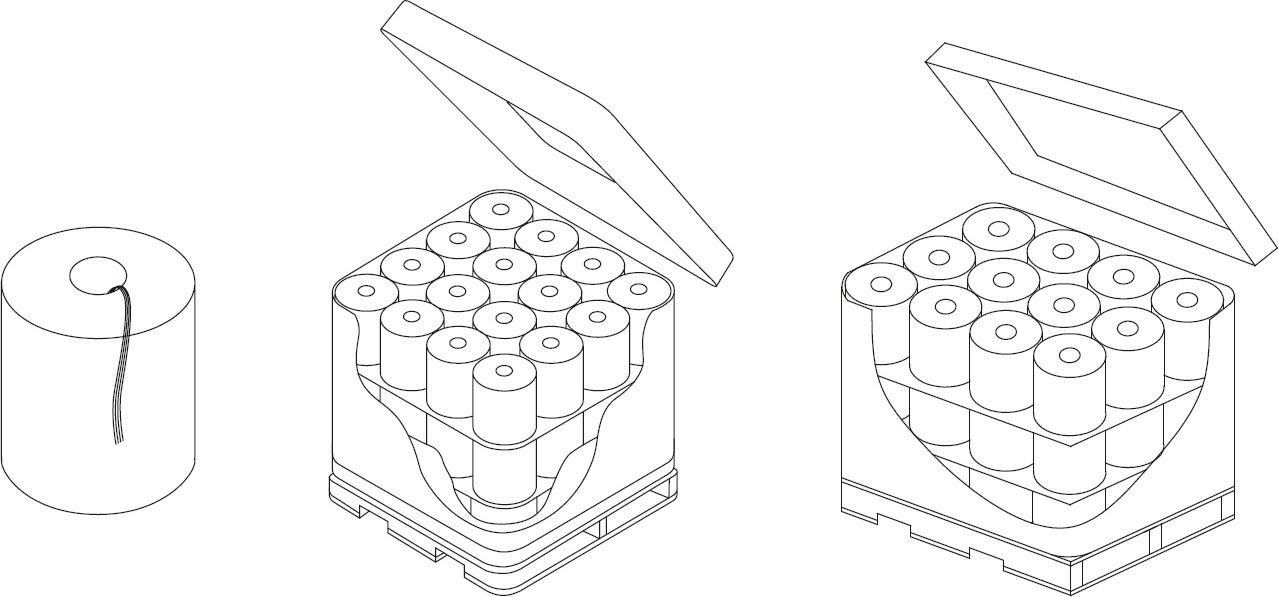

| Inani leeleya | 3 | 4 | 3 | 4 |

| Inani lee-doffs ngomaleko ngamnye | 16 | 12 | ||

| Inani leedoffs ngepallet nganye | 48 | 64 | 36 | 48 |

| Ubunzima obupheleleyo ngepallet nganye nge kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Ukuzulazula ngqo kweFiberglassUbude bepalethi mm (ngaphakathi) | 1120 (44.1) | 1270 (50.0) | ||

| Ukuzulazula ngqo kweFiberglassUbubanzi bepalethi mm (ngaphakathi) | 1120 (44.1) | 960 (37.8) | ||

| Ukuzulazula ngqo kweFiberglassUkuphakama kwepalethi mm (ngaphakathi) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Ngaphandle kokuba kuchazwe ngenye indlela,iimveliso zefiberglasskufuneka igcinwe kwindawo eyomileyo, epholileyo, nengafumiyo.

•Iimveliso zefiberglasskufuneka ihlale kwii-fiberglass ejikelezayo ngqoiphakheji yokuqala ide ifike ngaphambi kokuba isetyenziswe. Ubushushu begumbi kunye nokufuma kufuneka kugcinwe rhoqo kwi -10℃ ~ 35℃ kunye ne ≤80% ngokulandelelanayo.

• Ukuqinisekisa ukhuseleko kunye nokuphepha ukonakala kwemveliso, iipalethi akufuneki zibekwe ngaphezulu kweengqimba ezintathu ukuphakama.

• Xa iipallet zibekwe ngokweeleya ezimbini okanye ezintathu, kufuneka kuthathwe ingqalelo ekhethekileyo ukuze ipallet ephezulu ishukunyiswe ngokuchanekileyo nangokutyibilikayo.

Ukuba unemibuzo malunga neemveliso zethu okanye uluhlu lwamaxabiso, nceda usishiyele i-imeyile yakho kwaye siya kuqhagamshelana nathi kwiiyure ezingama-24.